Choosing the right drill bit is just as important as choosing the right drill. Many drilling problems—burned wood, broken bits, rough holes, or wasted time—happen simply because the wrong bit was used for the material. Wood, metal, and concrete all behave differently, and each requires a specific type of drill bit designed to handle its hardness, density, and structure.

In this guide, we will clearly explain drill bit types for wood, metal, and concrete, how they work, when to use them, and how to get clean, accurate results every time. Whether you’re a DIY beginner or a professional, this guide will help you drill smarter, safer, and more efficiently.

Why Drill Bit Selection Matters

At first glance, many drill bits look alike, which often leads people to use the same bit for every job. This is a common and costly mistake. Wood, metal, and concrete all respond differently to pressure, speed, and heat. Using the wrong drill bit can cause rough holes, overheating, broken bits, and unnecessary damage to both the tool and material.

- Wood can tear, splinter, or burn

- Metal creates heat and resistance

- Concrete requires impact and abrasion

Using the wrong bit can damage the material, create rough or inaccurate holes, overheat the drill, wear out the bit quickly, and increase the risk of slipping or breakage, making the drilling process slower, less efficient, and unsafe.

- Damage your workpiece

- Wear out the bit quickly

- Overheat your drill motor

- Create unsafe drilling conditions

That’s why understanding drill bit types is essential.

Drill Bit Types for Wood

Wood is softer than metal and concrete, but choosing the correct drill bit is still essential for clean, accurate holes. Wood drill bits are specially designed to cut through fibers smoothly, reducing splintering, tear-out, and burning while delivering better control and a cleaner finish.

1. Brad Point Drill Bits

Brad point bits are one of the best choices for woodworking projects where accuracy matters. The sharp center tip keeps the bit from wandering, allowing precise positioning before drilling begins. Their outer cutting edges slice wood fibers cleanly, producing smooth, splinter-free holes with excellent control and professional-looking results.

Best uses:

- Furniture making

- Cabinet work

- Precise hole placement

Advantages:

- Clean entry and exit holes

- Less splintering

- Excellent accuracy

2. Twist Drill Bits (Wood Use)

Standard twist bits can be used on wood for basic or rough drilling tasks where precision is not critical. However, they are not ideal for fine woodworking, as they can cause tear-out, splintering, and less accurate holes compared to wood-specific drill bits.

Best uses:

- Rough carpentry

- Quick drilling tasks

Limitations:

- Can cause tear-out

- Less precise than brad point bits

3. Spade Bits

Spade bits are flat, paddle-shaped drill bits with a sharp pointed tip at the center. They are designed for fast drilling of large-diameter holes in wood, making them ideal for rough construction tasks where speed matters more than a clean finish.

Best uses:

- Running wires through studs

- Rough construction

Pros and Cons:

- ✔ Fast and affordable

- ✘ Rough holes, not for finish work

4. Auger Bits

Auger bits are long drill bits with deep spiral flutes designed to pull wood chips out efficiently while drilling. Their threaded tip helps draw the bit into the wood smoothly, making them ideal for deep, straight holes in thick lumber or timber.

Best uses:

- Thick wood

- Deep holes

- Timber framing

Key benefit: They pull themselves into the wood with minimal pressure.

5. Hole Saws (Wood)

Hole saws are designed for cutting large-diameter holes in wood cleanly and efficiently. They consist of a circular saw blade attached to a drill and are commonly used for door locks, plumbing openings, electrical boxes, and ventilation holes. Hole saws provide smooth, round cuts and work best at low speeds with steady pressure to prevent overheating and tear-out.

Common uses:

- Door hardware

- Vent openings

- Electrical boxes

👉 Complete Guide to Drill & Drill Bit Types, Sizes, and Uses: This in-depth guide covers everything you need to know about drills and drill bits, from different types and sizes to their correct applications. Whether you’re a beginner or experienced, reading the full post will help you choose the right tools, avoid common mistakes, and achieve cleaner, more accurate drilling results.

Wood Drill Bit Summary Table

To help you choose the right drill bit for woodworking, here’s a quick summary of the most common types. This table highlights each bit’s best use, the quality of holes it produces, and the skill level required. It’s a handy guide for both beginners and experienced woodworkers alike.

| Drill Bit Type | Best For | Hole Quality | Skill Level |

|---|---|---|---|

| Brad Point | Precision woodworking | Very clean | Beginner–Pro |

| Twist Bit | General wood drilling | Average | Beginner |

| Spade Bit | Fast, large holes | Rough | Beginner |

| Auger Bit | Deep holes | Clean | Intermediate |

| Hole Saw | Large diameter holes | Clean edges | Intermediate |

Drill Bit Types for Metal

Drilling into metal requires more strength, precision, and careful heat management than wood. Metal drill bits are usually made from hardened steel, sometimes coated with materials like titanium to reduce friction and heat buildup. Using the right bit ensures cleaner holes, prevents bit wear, and reduces the risk of overheating or damaging your workpiece.

1. High-Speed Steel (HSS) Drill Bits

HSS drill bits are the most commonly used choice for metalwork. They are durable, versatile, and can handle a variety of metals with ease. These bits are affordable and can be sharpened multiple times, making them perfect for both beginners and experienced users. They work best when used with cutting oil to reduce heat.

Best uses:

-

Aluminum

-

Mild steel

-

Copper and brass

Advantages:

-

Affordable

-

Versatile

-

Easy to sharpen

2. Cobalt Drill Bits

Cobalt drill bits are designed for tough metals that generate a lot of heat. By containing a higher percentage of cobalt, these bits maintain hardness at high temperatures, allowing them to drill through stainless steel, hardened steel, and cast iron efficiently. They are slightly more expensive but essential for demanding metal projects.

Best uses:

-

Stainless steel

-

Hardened steel

-

Cast iron

Key benefit: They maintain hardness even at high temperatures.

3. Titanium-Coated Drill Bits

Titanium-coated drill bits are high-speed steel bits with a titanium nitride layer. The coating reduces friction and heat, extending the bit’s life and making repetitive drilling easier. These bits are ideal for light to medium metal projects. However, once the coating wears off, the bit behaves like standard HSS and loses its advantage.

Best uses:

-

Light to medium metal drilling

-

Repetitive work

Note: Once the coating wears off, performance drops.

4. Step Drill Bits

Step drill bits are cone-shaped and allow you to drill multiple hole sizes with a single bit. They are perfect for sheet metal, thin materials, and electrical panels. Step bits save time by eliminating frequent bit changes and create clean, precise holes with smooth edges, making them especially useful for professional or hobbyist metalwork.

Best uses:

-

Sheet metal

-

Electrical panels

-

Thin materials

Why they’re useful: No need to switch bits for different hole sizes.

5. Left-Handed Drill Bits

Left-handed drill bits rotate counterclockwise, unlike standard bits. This rotation makes them useful for removing broken bolts or screws while drilling. They are a specialized tool but extremely handy for maintenance work or situations where fasteners are stuck or damaged.

Special use case: They can loosen stuck fasteners while drilling.

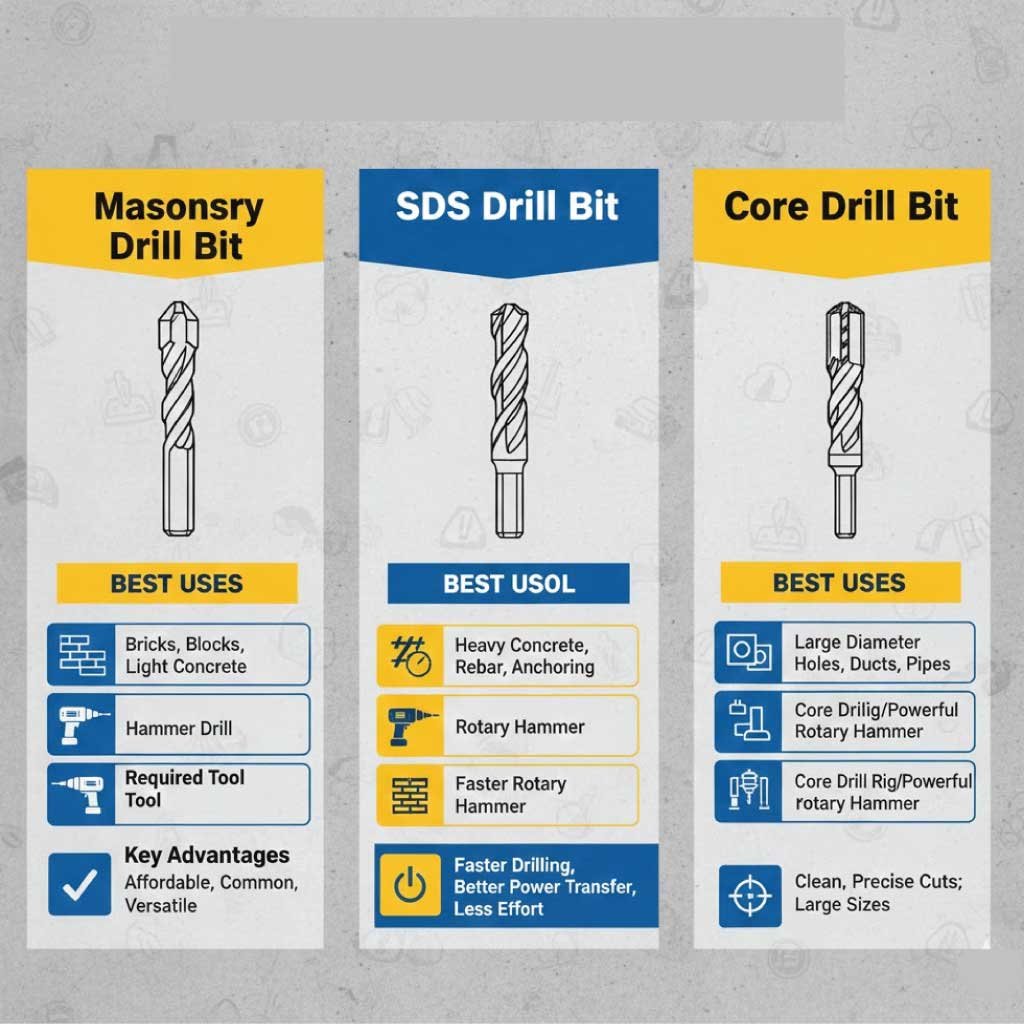

Drill Bit Types for Concrete & Masonry

Concrete and masonry are much harder than wood or metal. Drilling into these materials requires special masonry bits and usually a hammer drill. The right bit ensures effective penetration without cracking the material, reduces wear, and makes heavy-duty drilling safer and faster.

1. Masonry Drill Bits

Masonry bits feature a carbide tip that crushes concrete, brick, block, or stone rather than cutting it. They are designed to withstand the hardness of masonry while maintaining durability. Using a hammer drill with these bits makes drilling faster, reduces user fatigue, and provides more precise results for anchors or fixtures.

Best uses:

-

Concrete

-

Brick

-

Block

-

Stone

Important: They work best with a hammer drill.

2. SDS Drill Bits

SDS drill bits are intended for heavy-duty concrete work and are used with SDS rotary hammers. They handle reinforced concrete and structural projects effortlessly. SDS bits drill faster, require less manual pressure, and reduce fatigue, making them essential for professional construction or prolonged masonry work.

Best uses:

-

Reinforced concrete

-

Structural work

-

Professional construction

Advantages:

-

Faster drilling

-

Less user fatigue

3. Core Drill Bits

Core drill bits remove a cylindrical section of concrete rather than grinding through the entire area. They are ideal for creating larger openings without excessive effort. Core bits are often used for plumbing, HVAC installations, and other projects where a clean, precise circular hole is required.

Best uses:

-

Plumbing penetrations

-

HVAC openings

Concrete Drill Bit Comparison Table

This table provides a quick guide to choosing the right drill bit for concrete and masonry projects. It highlights the required tool, suitable material, and workload, helping you select the most efficient bit for any heavy-duty drilling task.

| Drill Bit Type | Tool Required | Material | Workload |

|---|---|---|---|

| Masonry Bit | Hammer drill | Brick, concrete | Light–Medium |

| SDS Bit | SDS rotary hammer | Reinforced concrete | Heavy |

| Core Bit | Core drill | Concrete walls | Very Heavy |

How to Choose the Right Drill Bit

Choosing the right drill bit is more than picking a piece of metal or carbide from the box. Each project has unique requirements, and selecting the correct bit ensures clean holes, longer tool life, and safer drilling. Consider the material, hole size, drill type, and desired finish before starting your work.

1- Material Type – Wood, Metal, or Concrete

Different materials respond differently to drilling. Wood is soft and forgiving, while metal is dense and heat-sensitive, and concrete is extremely hard. Using a bit designed for the material prevents splintering, overheating, or bit breakage, making your work faster, cleaner, and more efficient.

2- Hole Size – Diameter and Depth

The size of the hole determines which bit you need. Small-diameter holes require precision bits, while larger holes may need spade bits, hole saws, or core bits. Depth also matters: long or deep holes require bits that can remove debris efficiently without binding.

3- Drill Type – Standard Drill or Hammer Drill

The drill you use affects bit choice. Standard drills work well for wood and metal, while hammer drills or rotary hammers are needed for concrete and masonry. Matching the drill type to the bit ensures proper performance, reduces wear, and prevents unnecessary strain on your tool.

4- Finish Quality – Rough or Clean

Decide whether your project requires a rough hole or a precise, clean finish. Woodworking often demands smooth, tear-free holes, while construction tasks may prioritize speed over aesthetics. Choosing the right bit ensures your hole meets the desired quality without extra sanding or adjustments.

5- Avoiding Cheap or Incorrect Bits

Using the wrong or low-quality bit may seem convenient but often causes problems like rough holes, broken bits, and wasted time. Investing in the correct, durable bit for your material and project saves effort, ensures accuracy, and produces professional results every time.

Tips for Better Drilling Results

Mastering drilling technique is just as important as choosing the right drill bit. Small adjustments in speed, lubrication, and handling can make a big difference in hole quality, tool life, and safety. Follow these practical tips to achieve cleaner, more accurate holes while preventing bit damage and reducing fatigue during any project.

-

Use low speed for metal and concrete

-

Apply cutting oil when drilling metal

-

Let the bit do the work—don’t force it

-

Clear debris frequently

-

Replace dull bits immediately

Proper technique extends tool life and improves accuracy.

Common Drill Bit Mistakes to Avoid

Even experienced DIYers and professionals can make costly drill bit mistakes. Using the wrong technique or bit can damage your tools, ruin your workpiece, and slow down projects. Being aware of common errors helps prevent accidents, extend bit life, and ensures cleaner, more precise holes every time.

Common Mistakes to Avoid

-

Using wood bits on metal

-

Drilling concrete without a hammer function

-

Applying too much pressure

-

Ignoring heat buildup

-

Using worn or chipped bits

Avoiding these mistakes can save time, money, and frustration.

Final Thoughts

Understanding drill bit types for wood, metal, and concrete makes drilling easier, safer, and more precise. Each bit is designed with a specific purpose, and using the right one ensures clean holes, longer tool life, and professional results.

Whether you’re building furniture, working on metal projects, or installing anchors in concrete, the correct drill bit makes all the difference. Invest in quality bits, learn their uses, and your drilling tasks will become smoother and more efficient every time.