When working on mechanical, construction, automotive, or DIY projects, selecting the correct nut size is just as important as choosing the right bolt. A nut that doesn’t fit properly can cause loose joints, stripped threads, or even complete mechanical failure. That’s why understanding nut sizes, standards, materials, and applications is essential for both professionals and beginners.

This detailed guide will walk you through nut size charts, different types of nuts, measurement standards, materials, and real-world applications. You’ll also learn how to measure nut size correctly and how to measure a nut for socket size, so you can confidently choose the right tool every time.

What Is a Nut and Why Size Matters

A nut is a threaded fastener designed to work together with a bolt, screw, or threaded rod to securely join two or more components. It uses internal threads to engage with the external threads of a bolt, allowing pressure to be evenly distributed. When tightened properly, this connection creates a strong, stable, and load-bearing joint suitable for many mechanical and structural applications.

Nut size matters because:

- Incorrect sizing can strip threads

- Loose nuts cause vibration and failure

- Oversized tools damage edges

- Wrong standards (metric vs SAE) cause poor fit

Understanding nut sizes saves time, money, and frustration.

Nut Size Chart Explained

A nut size chart helps you quickly identify the correct nut by showing key measurements such as thread diameter, thread pitch, and width across flats (WAF). These charts are essential for ensuring proper fit, tool selection, and safe fastening. Most nut size charts are divided into Metric (ISO) and SAE (Imperial) standards, making it easier to match nuts with compatible bolts and tools.

Metric Nut Size Chart (ISO)

Metric nuts are measured in millimeters and identified by thread diameter and pitch, which represents the distance between threads, making them easier to standardize and widely used worldwide.

| Thread Size | Pitch (mm) | Wrench Size (mm) |

|---|---|---|

| M4 | 0.7 | 7 mm |

| M5 | 0.8 | 8 mm |

| M6 | 1.0 | 10 mm |

| M8 | 1.25 | 13 mm |

| M10 | 1.5 | 17 mm |

| M12 | 1.75 | 19 mm |

| M16 | 2.0 | 24 mm |

SAE (Imperial) Nut Size Chart

SAE nuts are measured in inches and identified by threads per inch (TPI), a system commonly used in the United States for automotive, industrial, and mechanical applications.

| Thread Size | Threads per Inch | Wrench Size (inches) |

|---|---|---|

| 1/4″ | 20 | 7/16″ |

| 5/16″ | 18 | 1/2″ |

| 3/8″ | 16 | 9/16″ |

| 1/2″ | 13 | 3/4″ |

| 5/8″ | 11 | 15/16″ |

| 3/4″ | 10 | 1-1/8″ |

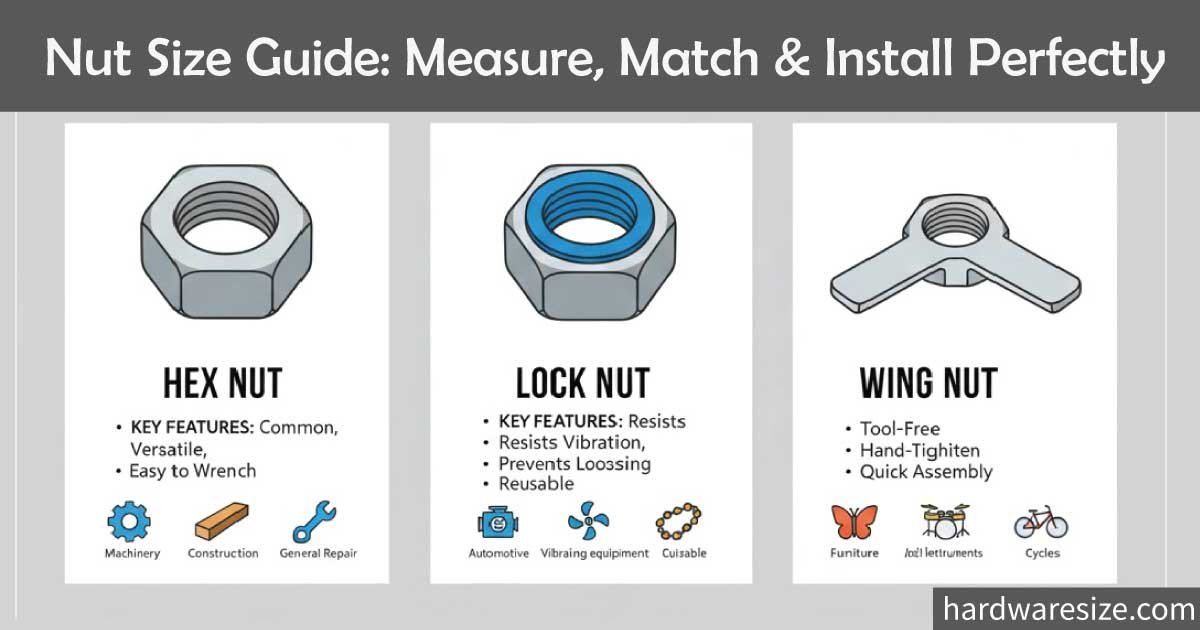

Types of Nuts and Their Applications

Different types of nuts are designed to handle specific fastening needs based on strength, vibration resistance, appearance, and ease of use. Selecting the correct nut improves safety, durability, and overall performance in mechanical, construction, and DIY projects of all sizes.

1. Hex Nuts

Hex nuts are the most commonly used fasteners due to their six-sided shape, which provides excellent grip for wrenches and sockets. They are easy to install and remove, offer strong clamping force, and are compatible with a wide range of bolts, making them suitable for both light-duty and heavy-duty fastening tasks.

Applications: Used in structural joints, machinery frames, automotive engines, construction hardware, and general-purpose mechanical assemblies requiring reliable strength.

2- Lock Nuts

Lock nuts are designed to prevent loosening caused by vibration, movement, or repeated stress. They achieve this through nylon inserts, distorted threads, or added friction. Lock nuts maintain consistent tension over time, reducing the risk of failure in critical connections where safety and long-term stability are essential.

Applications: Commonly used in automotive suspension systems, heavy machinery, industrial equipment, and assemblies exposed to vibration or constant motion.

3. Wing Nuts

Wing nuts feature two extended wings that allow tightening and loosening by hand without the need for tools. They are ideal for applications requiring frequent adjustment or removal. While they are not designed for heavy loads, wing nuts offer convenience, speed, and ease of use in light-duty fastening situations.

Applications : Used in temporary assemblies, furniture setups, display fixtures, DIY projects, and light-duty installations needing quick adjustments.

4. Cap Nuts (Acorn Nuts)

Cap nuts, also called acorn nuts, have a rounded, closed-end design that covers exposed bolt threads. This improves safety by eliminating sharp edges and enhances appearance in visible installations. Cap nuts also help protect threads from dirt, moisture, and corrosion, extending the life of the fastener.

Applications: Used in decorative hardware, safety-focused installations, furniture fittings, outdoor fixtures, and applications where exposed threads must be covered.

5. Flange Nuts

Flange nuts include a built-in washer at the base that evenly distributes pressure over a wider surface area. This design reduces material damage and improves load distribution. The flange also provides extra resistance to loosening, making these nuts effective in assemblies exposed to vibration or uneven surfaces.

Applications: Widely used in automotive assemblies, sheet metal work, mechanical joints, and applications requiring even load distribution.

6. Square Nuts

Square nuts have four flat sides that provide increased surface contact and better resistance to rotation compared to hex nuts. Their shape allows them to grip wood and rough materials more effectively. Square nuts are often preferred in traditional, restoration, and woodworking projects where stability during tightening is important.

Applications: Commonly used in woodworking, furniture restoration, vintage machinery, and projects requiring improved grip on uneven surfaces.

Nut Standards and Specifications

Nut standards and specifications ensure that fasteners fit correctly, perform safely, and meet strength requirements. These standards define thread dimensions, tolerances, materials, and load ratings. Following recognized standards helps prevent thread damage, improper fitting, and mechanical failure, especially in professional, industrial, and safety-critical applications.

Common Nut Standards

ISO (Metric): ISO standards define metric nut sizes, thread pitch, and tolerances, ensuring global compatibility, consistent quality, and reliable fastening across international mechanical and industrial applications.

DIN: DIN standards are German industrial specifications known for precision and consistency, widely used in Europe and globally for high-quality engineering and mechanical fasteners.

ASTM: ASTM standards focus on material composition, mechanical strength, and testing requirements, ensuring nuts meet strict performance, safety, and durability standards in demanding environments.

SAE: SAE standards govern imperial fasteners, specifying dimensions, thread forms, and strength grades commonly used in automotive, industrial, and mechanical applications in the United States.

Always match the nut standard with the bolt standard to avoid thread mismatch.

Nut Materials and Their Uses

The material of a nut plays a major role in determining its strength, durability, corrosion resistance, and overall performance. Choosing the right nut material ensures safe fastening, longer service life, and suitability for specific environments such as moisture, heat, vibration, or heavy mechanical loads.

1. Steel Nuts

Steel nuts are strong, affordable, and widely used in general fastening applications. They are often zinc-plated or coated to improve corrosion resistance and extend lifespan. Steel nuts provide reliable clamping force and durability, making them suitable for everyday mechanical, construction, and automotive fastening tasks.

2. Stainless Steel Nuts

Stainless steel nuts offer excellent resistance to rust, corrosion, and chemical exposure. They maintain strength and appearance even in harsh environments. These nuts are ideal where hygiene, moisture resistance, and long-term durability are required, especially in outdoor, marine, and food-related installations.

3. Brass Nuts

Brass nuts are corrosion-resistant, non-magnetic, and non-sparking, making them suitable for specialized applications. They are softer than steel, which reduces thread damage in delicate assemblies. Brass nuts are also valued for their attractive finish, making them useful in visible or decorative installations.

4. Nylon and Plastic Nuts

Nylon and plastic nuts are lightweight, electrically insulating, and resistant to chemicals and moisture. They are ideal for applications where metal fasteners could cause conductivity issues or unnecessary weight. These nuts are best suited for low-load, non-structural, and sensitive electronic or household assemblies.

5. Alloy Steel Nuts

Alloy steel nuts are heat-treated to provide exceptional strength, hardness, and wear resistance. They are designed to handle high loads, pressure, and stress without deformation. These nuts are commonly used in demanding mechanical environments where safety, durability, and performance are critical.

How to Measure a Nut for Socket Size

Choosing the correct socket size is essential to prevent rounding, slipping, or damaging the nut. Accurate measurement ensures proper torque, secure fastening, and efficient work. This is important for mechanical, automotive, construction, and DIY projects.

Follow These Steps

To select the right socket, start by measuring the nut’s width across flats (WAF). Confirm whether the nut is metric or SAE and match it to the corresponding socket. Always test the fit before applying force, and use a caliper or socket gauge for precise measurement.

1. Measure the Width Across Flats

The width across flats (WAF) is the key measurement for choosing a socket. It is the distance between two opposite flat sides of the nut. Measuring this accurately ensures the socket fits snugly, reducing the risk of rounding off or slipping during tightening or loosening.

2. Match Metric or SAE

Always ensure that the socket type matches the nut standard. Metric nuts require metric sockets, and SAE nuts require SAE sockets. Even if dimensions appear similar, mixing standards can lead to poor fit, stripped threads, and damaged tools, making proper matching essential for safe and effective fastening.

3. Test Fit Before Applying Force

Before applying torque, slide the socket onto the nut to check the fit. It should sit snugly without wobbling or rocking. Testing ensures that force is evenly applied, preventing rounding off, stripped threads, or injury. Always adjust or switch sockets if there is any looseness.

4. Use a Caliper or Socket Gauge

For precise measurement, especially in professional or high-stress applications, use a caliper or a socket gauge. These tools measure the width across flats accurately, ensuring correct socket selection. Accurate measurement prevents damage, improves efficiency, and guarantees a secure, reliable connection in mechanical or construction tasks.

Common Mistakes When Selecting Nut Sizes

Selecting the wrong nut size can lead to stripped threads, loose connections, or mechanical failure. Avoiding common mistakes ensures proper fit, safety, and durability in mechanical, automotive, construction, and DIY projects. Understanding these pitfalls helps achieve reliable fastening and prevents costly repairs or damage to components.

Mixing Metric Nuts with SAE Bolts: Combining metric nuts with SAE bolts causes thread mismatch, loose connections, and potential damage to both the nut and bolt.

Using Adjustable Wrenches Instead of Proper Sockets: Relying on adjustable wrenches can round off nut edges; using the correct socket ensures proper grip and torque application.

Ignoring Thread Pitch Differences: Not checking thread pitch may result in mismatched threads, stripped fasteners, and insecure connections, compromising strength and safety.

Over-Tightening Smaller Nuts: Excessive force on small nuts can strip threads, deform components, or damage the bolt, reducing the joint’s reliability.

Using Soft Material Nuts in High-Load Applications: Soft material nuts cannot withstand heavy loads, leading to deformation, loosening, or mechanical failure under stress or vibration.

Avoiding These Mistakes Improves Safety and Longevity: Following proper sizing practices ensures secure connections, extends fastener life, and maintains safety, reliability, and performance in all assemblies.

Practical Applications of Nut Size Charts

Nut size charts are valuable tools for mechanics, builders, and DIY enthusiasts. They help quickly identify correct nut dimensions, ensuring proper fit and avoiding mistakes. Using these charts saves time, prevents thread damage, and improves efficiency in automotive repair, construction, furniture assembly, industrial maintenance, and other mechanical or fabrication projects.

Automotive Repair: Nut size charts help identify the correct fasteners for engines, suspension systems, and body components, ensuring safe, precise repairs.

Construction Projects: Charts assist builders in selecting proper nuts for structural connections, preventing loose joints and ensuring stability in construction assemblies.

Furniture Assembly: Using size charts ensures correct nuts are used for furniture, avoiding stripped threads and improving durability and safety of assemblies.

Industrial Maintenance: Nut size charts help maintenance personnel quickly match replacement nuts to machinery, minimizing downtime and preventing equipment failure.

DIY Home Improvement: Home projects benefit from nut charts by providing accurate sizing for fasteners, ensuring secure and professional-quality assembly.

Manufacturing and Fabrication: Manufacturers use nut charts to standardize assembly, ensure component compatibility, and maintain consistent quality across production lines.

Whether you’re repairing a car, assembling furniture, or managing an industrial project, knowing how to measure nut size and how to measure a nut for socket size gives you confidence and precision in your work.

Save this guide, bookmark a nut size chart, and your next project will be smoother, safer, and more professional.

👉 Choosing the right bolt is crucial for safe and efficient mechanical projects. Our Perfect Bolt Selection Guide walks you through bolt types, materials, sizes, and standards, helping you avoid common mistakes and ensure strong, reliable connections. Read the full guide to master bolt selection, improve your projects, and work with confidence every time.