Bolts may look simple at first glance, but choosing the right bolt size is one of the most important steps in any mechanical, construction, automotive, or DIY project. A wrong bolt size can lead to loose joints, damaged threads, safety risks, or even complete system failure. That’s why understanding bolt size charts is not just for engineers—it’s useful for anyone who works with tools.

In this guide, we’ll break down bolt size charts in a clear, practical way. You’ll learn what diameter, length, and thread types actually mean, how they are measured, and how to confidently select the correct bolt for your application.

Why Bolt Size Matters More Than You Think

Bolts are designed to hold parts together under load, vibration, heat, and pressure. If a bolt is too thin, it may snap. If it’s too thick, it may not fit the hole. If the threads don’t match, the bolt will damage the nut or tapped hole.

Many failures in machines and structures don’t happen because of bad materials—but because the wrong fastener was used. Understanding bolt size charts helps you avoid these mistakes and saves time, money, and frustration.

Understand Bolt Size Charts:

Bolt size charts are essential references for anyone working with fasteners. They provide key information about bolts in a clear, standardized format, helping you select the right bolt for your project. Understanding these charts ensures accurate assembly, prevents mistakes, and saves time.

| Bolt Feature | Description |

|---|---|

| Bolt Diameter | The thickness of the bolt’s shank, measured in mm (metric) or inches (imperial). |

| Bolt Length | Measured from under the head to the tip of the bolt (not including the head). |

| Thread Pitch / TPI | Distance between threads (metric) or threads per inch (imperial). |

| Head Size | Wrench or socket size required to tighten the bolt. |

| Standard Type | Specifies whether the bolt is metric or imperial. |

At first, these charts may look confusing, but once you understand the basic terms, they become very easy to read.

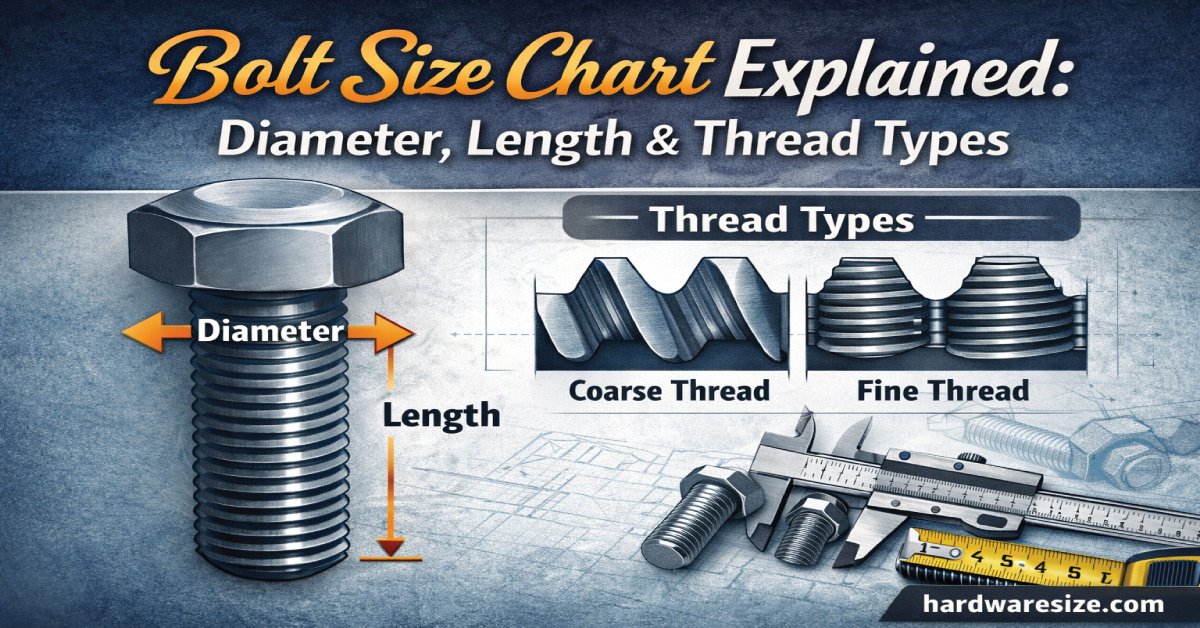

Bolt Diameter Explained (The First and Most Important Measurement)

Bolt diameter is the most crucial measurement when selecting bolts, as it affects strength, fit, and compatibility with holes or nuts. It refers to the thickness of the bolt’s shank and is used to identify the bolt’s overall size. Understanding diameter helps ensure the right bolt is chosen for any project.

What Is Bolt Diameter?

Bolt diameter is one of the most important measurements when working with bolts. It refers to the thickness of the bolt’s shank and is the main factor in determining strength, fit, and compatibility with nuts or holes. Knowing the diameter ensures you choose the correct bolt for any application.

- Metric bolts use millimeters (mm)

- Imperial bolts use inches or fractional sizes

Common Examples

Here are some typical bolt diameter examples to help you quickly understand how sizes are labeled in both metric and imperial systems. These examples show the actual thickness of the bolt’s shank, making it easier to visualize and select the correct bolt for your project or match it to the proper hole or nut.

- M6 bolt → 6 mm diameter

- M8 bolt → 8 mm diameter

- 1/4″ bolt → 0.25 inch diameter

- 1/2″ bolt → 0.5 inch diameter

In bolt size charts, diameter is always listed first because it determines strength and hole compatibility.

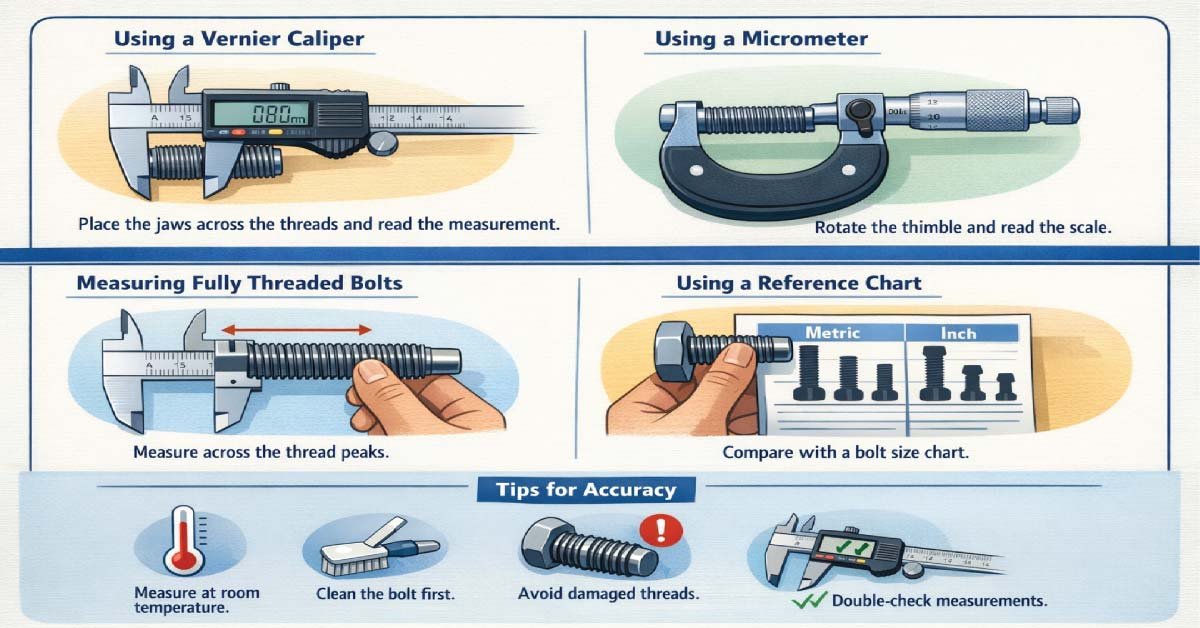

How to Measure Bolt Diameter

Measuring bolt diameter accurately ensures you select the right bolt for your project. Using the correct tools and techniques prevents mistakes, saves time, and guarantees a proper fit. Here’s a step-by-step guide to measuring bolt diameter efficiently, whether you have precision tools or just a reference chart.

1. Using a Vernier Caliper:

A Vernier caliper is the most precise tool for measuring bolt diameter. Place the jaws across the threaded portion of the bolt and read the measurement. Ensure the caliper is perpendicular to the threads for accuracy. This method works for both metric and imperial bolts, giving you an exact diameter.

2. Using a Micrometer:

A micrometer is another highly accurate tool for measuring bolt thickness. Place the bolt between the spindle and anvil, then rotate the thimble until it fits snugly. Read the scale for the measurement. Micrometers are ideal for small bolts or when extreme precision is needed.

3. Measuring Fully Threaded Bolts

For fully threaded bolts, measure across the external threads at multiple points to account for variations. Avoid measuring the valleys of the threads; focus on the peaks. Take an average if there is a slight difference, ensuring a reliable measurement that matches chart specifications.

4. Using a Reference Chart:

If you don’t have measuring tools, compare the bolt to a known bolt size from a chart. Place your bolt alongside the charted dimensions to identify the closest match. This method is less precise but effective for general projects or quick identification.

5. Tips for Accuracy:

Always measure at room temperature and clean the bolt before measuring. Avoid damaged or worn threads, as they can give false readings. Double-check your measurements for critical projects. Accurate diameter measurement ensures proper assembly, safety, and compatibility with nuts or drilled holes.

Bolt Length Explained (How Long Is Long Enough?)

Bolt length is a key measurement that determines how well a bolt holds materials together. It is measured from under the head to the tip, ensuring proper thread engagement. Choosing the correct length prevents weak joints or interference and ensures secure, reliable assemblies in both metric and imperial systems.

1- What Is Bolt Length?

Bolt length is measured from under the head to the tip of the bolt, not including the head itself (except for countersunk bolts). This is a common mistake beginners make—measuring the total length including the head. Most bolt size charts assume length is measured correctly.

2- Why Bolt Length Is Important

Choosing the correct bolt length is essential for a secure and reliable connection. Too short, and the threads won’t engage properly; too long, and the bolt may bottom out or interfere. The right length ensures a strong, stable joint.

-

Too short → not enough thread engagement

-

Too long → bottoming out or interference

-

Correct length → strong, secure joint

3- Typical Bolt Lengths

Bolt lengths vary depending on the application and material thickness. Knowing typical lengths helps you quickly select the right bolt for your project. Metric bolts come in standard sizes that are commonly used in machinery, construction, and DIY projects.

Metric bolts:

-

10 mm

-

20 mm

-

30 mm

-

50 mm

Imperial bolts:

-

1 inch

-

1½ inch

-

2 inches

Bolt size charts usually list diameter first, then length. Example: M8 × 40 means 8 mm diameter and 40 mm length.

Bolt Thread Types Explained (The Key to Proper Fit)

Threads are the spiral ridges on a bolt that allow it to engage securely with a nut or threaded hole. Even when the diameter and length are correct, using the wrong thread type can lead to poor fit, stripped threads, or a weak joint. Understanding thread type is essential for proper assembly and reliable fastening.

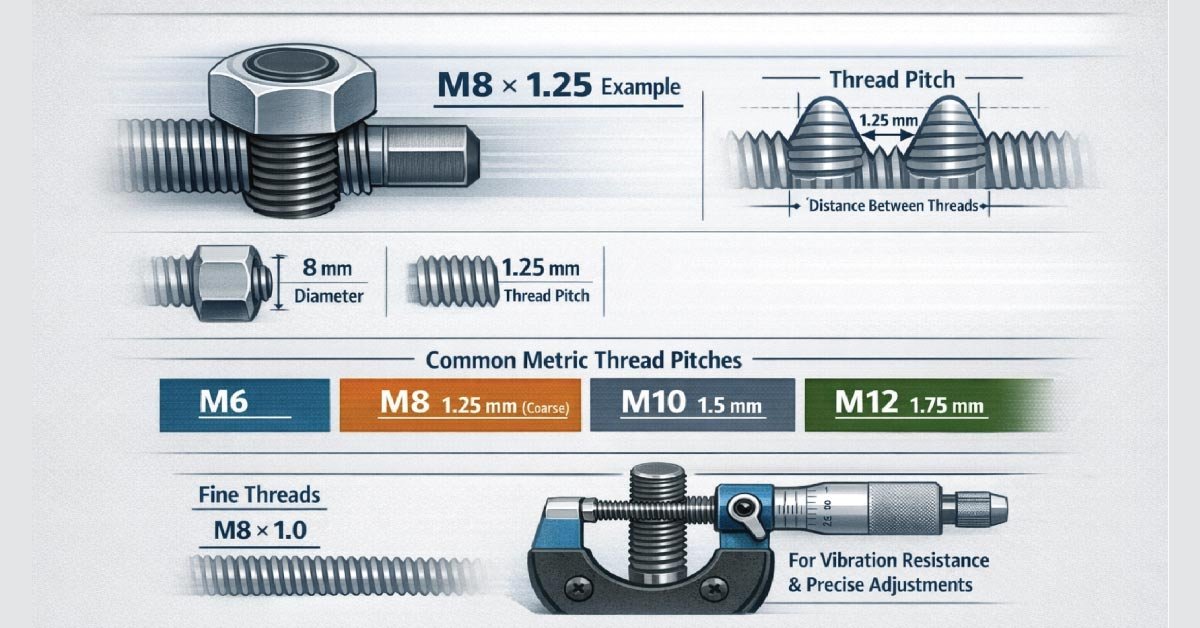

1- Metric Thread Types (M Series)

Metric bolts use a system called thread pitch, which measures the distance between each thread in millimeters. Understanding thread pitch is crucial for matching bolts with nuts or tapped holes. Choosing the correct metric thread type ensures proper fit, prevents stripped threads, and guarantees a secure and reliable fastening in any application.

Example

M8 × 1.25

8 mm diameter

1.25 mm distance between threads

Common Metric Thread Pitches

- M6 → 1.0 mm

- M8 → 1.25 mm (coarse)

- M10 → 1.5 mm

- M12 → 1.75 mm

Fine threads also exist, such as M8 × 1.0, and are used where vibration resistance or precise adjustment is needed.

Imperial Thread Types (UNC, UNF, and More)

Imperial bolts are measured using threads per inch (TPI) rather than millimeter pitch. Understanding TPI is essential for matching bolts with compatible nuts or tapped holes. Choosing the correct imperial thread type, such as UNC or UNF, ensures a proper fit, prevents thread damage, and provides a strong, secure connection in any assembly.

Common Imperial Thread Types

Imperial bolts come in different thread types, each designed for specific applications. Coarse threads (UNC) are strong and easy to assemble, while fine threads (UNF) provide better precision and resist loosening from vibration. Knowing the differences helps you select the right bolt for strength, fit, and reliability in any project.

-

UNC (Unified National Coarse)

-

Fewer threads

-

Strong and easier to assemble

-

-

UNF (Unified National Fine)

-

More threads per inch

-

Better for vibration and precision

-

Bolt size charts always specify whether the bolt is UNC or UNF.

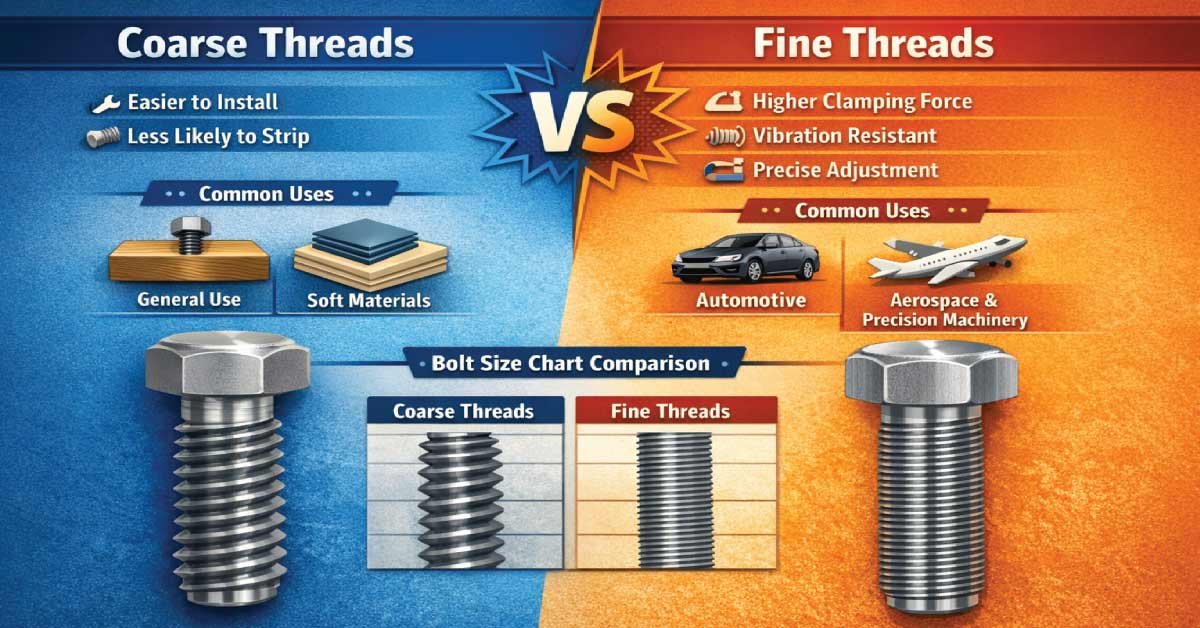

Coarse vs Fine Threads (Which One Should You Use?)

Coarse and fine threads serve different purposes depending on the material and application. Coarse threads are easier to install, less likely to strip, and ideal for general use, while fine threads offer higher clamping force, better vibration resistance, and precise adjustments, making them suitable for automotive and aerospace projects. Bolt size charts help compare both types quickly.

| Thread Type | Advantages | Common Applications |

|---|---|---|

| Coarse Threads | Easier to install, less likely to strip | General use, soft materials |

| Fine Threads | Higher clamping force, better resistance to vibration, precise adjustment | Automotive, aerospace, precision machinery |

Standard Bolt Size Chart Overview (Metric Example)

A standard metric bolt size chart provides a clear layout of all essential dimensions. It shows bolt diameters, standard thread pitches, available lengths, and corresponding nut sizes. Understanding this format allows you to quickly select the correct bolt for any project, saving time and preventing assembly errors.

| Diameter | Standard Pitch (mm) | Available Lengths (mm) | Matching Nut Size |

|---|---|---|---|

| M6 | 1.0 | 10, 20, 30, 40 | M6 |

| M8 | 1.25 | 20, 30, 40, 50 | M8 |

| M10 | 1.5 | 30, 40, 50, 60 | M10 |

| M12 | 1.75 | 40, 50, 60, 70 | M12 |

Once you understand the format, reading a chart takes seconds.

Bolt Head Sizes and Their Role

Bolt head size indicates the wrench or socket needed to tighten or loosen a bolt. Size charts include this information to help you select the correct tools and plan for workspace constraints. Knowing head sizes ensures efficient assembly, prevents damage, and makes working in tight spaces easier.

Example

-

M8 bolt → 13 mm head

-

M10 bolt → 17 mm head

This is useful when selecting tools or working in tight spaces.

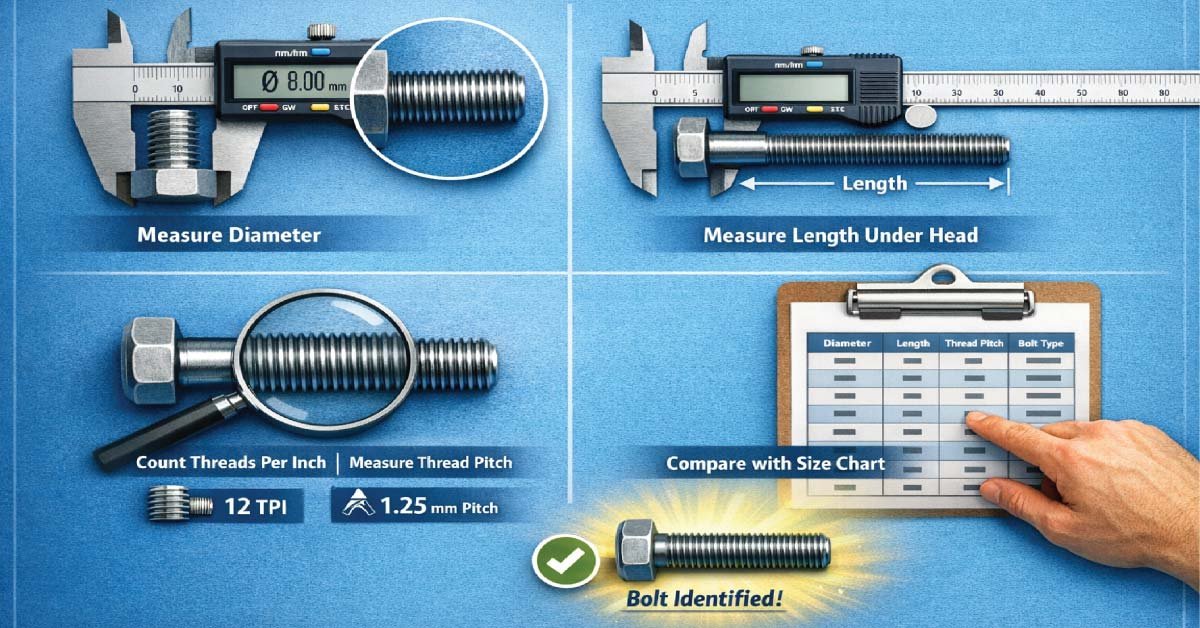

How to Identify an Unknown Bolt Using a Size Chart

Identifying an unknown bolt is easy when you use a size chart. By measuring the diameter, length, and thread pitch or threads per inch, you can quickly compare the values to a chart. Within minutes, you’ll know the exact bolt type, ensuring proper replacement or assembly.

Steps:

-

Measure the diameter with a caliper

-

Measure the length under the head

-

Count threads per inch or measure pitch

-

Compare values with a bolt size chart

Within minutes, you will know exactly what bolt you have.

Common Bolt Size Mistakes to Avoid

Bolts may seem simple, but small errors can cause major problems. Choosing the wrong size, mixing standards, or ignoring thread specifications can lead to stripped threads, weak joints, or assembly issues. Understanding common mistakes helps ensure strong, safe, and reliable fastenings in any project.

1- Mixing Metric and Imperial

Metric and imperial bolts may appear similar, but they are not interchangeable. For example, an M8 bolt looks close to a 5/16″ bolt. Using one in place of the other can damage threads and compromise the joint, so always match the standard carefully.

2- Ignoring Thread Pitch

Even if the diameter matches, thread pitch or TPI must be correct. Using a bolt with the wrong thread type can prevent proper engagement, strip threads, or weaken the connection. Always check the pitch before assembly to ensure a secure and reliable joint.

3- Using the Wrong Length

Choosing a longer bolt does not guarantee better performance. A bolt must have the correct length for proper thread engagement without bottoming out. Selecting the proper length ensures a strong joint, prevents interference, and maintains overall assembly integrity.

Bolt Strength Grades (Quick Mention)

Bolt strength is just as important as size when selecting fasteners. Different applications require different strength levels to ensure safety and durability. Metric grades (8.8, 10.9, 12.9) and imperial grades (Grade 5, Grade 8) indicate tensile strength. Always match the correct size with the proper strength rating.

-

Metric grades: 8.8, 10.9, 12.9

-

Imperial grades: Grade 5, Grade 8

Always pair the correct size with the correct strength rating.

When to Use a Bolt Size Chart:

Bolt size charts are essential tools for both professionals and beginners. They are used in a wide range of tasks, from assembling machinery, performing automotive repairs, and installing furniture, to metal fabrication, construction, and DIY home projects. Using a size chart ensures the correct diameter, length, and thread type are chosen, preventing mistakes, saving time, and guaranteeing strong, reliable, and safe fastenings in every project.

Practical Tips for Beginners

For beginners, working with bolts can be tricky without proper guidance. Following practical tips ensures accurate selection, safe assembly, and prevents damage. Simple habits like keeping charts handy, using thread gauges, labeling parts, and matching standards make bolt work easier, faster, and more reliable, helping both DIYers and professionals avoid costly mistakes.

-

Keep a printed bolt size chart in your workshop

-

Use thread gauges if available

-

Never force a bolt that doesn’t turn easily

-

Label bolts when disassembling machines

-

Match bolt, nut, and washer standards

These simple habits prevent costly errors.

Final Thoughts

Bolt size charts may look technical, but once you understand diameter, length, and thread types, everything becomes simple. Think of bolts like keys—only the right size fits perfectly.

Whether you’re a mechanic, engineer, fabricator, or DIY enthusiast, knowing how to read and use a bolt size chart gives you confidence and precision in your work. Instead of guessing, you’ll choose the right bolt every time—and that’s how strong, reliable assemblies are built.

👉 Removing a broken bolt can be tricky, but with the right tools, tips, and techniques, it’s completely manageable. Our step-by-step guide covers everything from choosing the proper extractor to avoiding damage. Read the full post to learn how to tackle stuck or broken bolts safely and efficiently.