A drill is one of the most commonly used tools in homes, workshops, and construction sites. From basic DIY tasks like hanging shelves to professional jobs involving metal fabrication or concrete drilling, drills make work faster, cleaner, and more precise.

However, many users struggle to understand which drill is right for their task. Some drills are built for light household use, while others are designed to handle concrete, stone, or heavy-duty fastening. Using the wrong drill can damage materials, break drill bits, or even cause injury.

This complete drill and drill bit guide is written to solve that problem. In this first part, we will focus on types of drills, how they work, and where each one is best used. Later parts will cover drill bit types, sizes, charts, and practical usage tips, helping you make the right choice every time.

What Is a Drill and Why Is It So Important?

A drill is a widely used hand or power tool designed to create round holes and drive screws or fasteners into different materials. It operates by rotating a drill or driver bit at high speed. Some drills also include a hammering mechanism, which helps break through tough surfaces such as concrete, brick, and masonry with ease.

Drills are essential because they:

- Save time compared to manual tools

- Create clean, accurate holes

- Allow controlled fastening and screw driving

- Work across multiple materials like wood, metal, plastic, and concrete

Modern drills are designed to be versatile, meaning one tool can handle multiple tasks when paired with the correct drill bit.

How a Drill Works (Simple Explanation)

At its core, a drill transfers power from a motor to a rotating chuck that holds the drill bit. When pressure is applied, the rotating bit cuts into the material. Some drills add extra force through a hammering action, which helps break apart hard materials like masonry.

The effectiveness of a drill depends on:

- Power (voltage or motor strength)

- Speed (RPM control)

- Torque (rotational force)

- Correct drill bit selection

Understanding these basics helps you avoid common problems such as overheating, bit slipping, or rough holes.

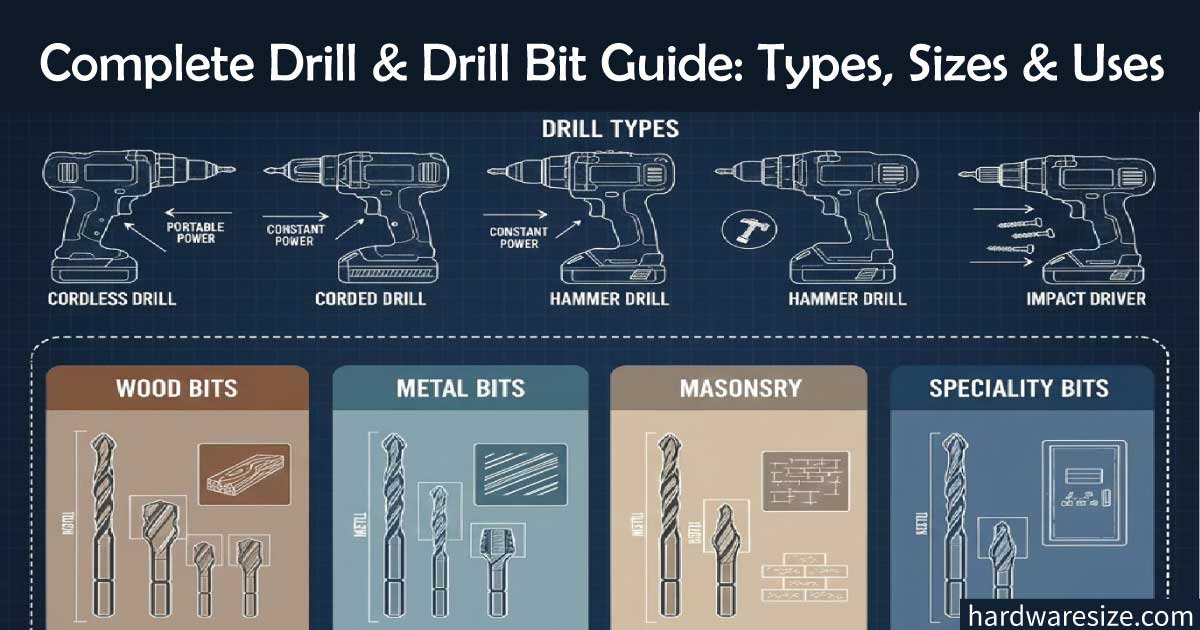

Main Types of Drills Explained Clearly

Instead of listing tools randomly, it’s better to understand drills by purpose and workload. A drill is a widely used hand or power tool designed to create round holes and drive screws into different materials. It works by rotating a drill bit at high speed, and some models include a hammering action for hard surfaces like concrete and masonry.

1- Cordless Drill – The Everyday All-Purpose Tool

The cordless drill is the most widely used drill today. It runs on a rechargeable battery, making it easy to carry and use anywhere without worrying about power outlets.

It is commonly used for drilling holes in wood, plastic, and thin metal, as well as for driving screws. Most cordless drills include adjustable speed settings and torque control, allowing better precision during work.

For homeowners and DIY users, a cordless drill is usually the first and most useful purchase.

2- Corded Drill – Consistent Power for Long Jobs

A corded drill connects directly to an electrical outlet and delivers constant power. Unlike cordless drills, it does not lose performance over time due to battery drain.

Corded drills are preferred for extended work sessions, especially when drilling metal or thick wood. They are generally more powerful than entry-level cordless models but lack portability.

If you work in a fixed location and need uninterrupted power, a corded drill is a solid option.

3- Hammer Drill – Designed for Masonry

A hammer drill looks similar to a standard drill but includes a built-in hammering mechanism. While rotating, the bit also moves forward and backward, creating rapid impacts. This combined motion helps break through hard materials like concrete, brick, and stone, making it ideal for masonry drilling tasks.

Hammer drills are ideal for:

- Concrete walls

- Brick surfaces

- Masonry anchors

They are not meant for heavy demolition but work well for household masonry tasks.

4- Rotary Hammer Drill – Heavy-Duty Professional Tool

A rotary hammer drill uses a pneumatic system instead of a mechanical hammering action. This allows it to deliver much stronger impact force.

These drills are commonly used in construction and industrial settings for drilling large holes in concrete or stone. Most models use SDS or SDS-Plus bits, which lock securely into the chuck.

For average home users, this tool is usually unnecessary, but for professionals, it is essential.

5- Impact Driver – Powerful Fastening Tool

Although often confused with drills, impact drivers are mainly designed for driving screws and bolts. They deliver high torque in short, powerful bursts, which reduces strain on the user. This makes them extremely effective for installing long, thick, or stubborn fasteners in wood and metal.

Impact drivers are commonly used in:

- Deck building

- Framing

- Structural fastening

They are not ideal for precision drilling but excel at heavy fastening jobs.

Drill Types Comparison Table

This drill types comparison table helps you quickly understand the differences between common drills. It highlights power sources, best use cases, and limitations, making it easier to choose the right drill for DIY projects, construction work, precision drilling, or heavy-duty tasks without confusion or guesswork.

| Drill Type | Power Source | Best For | Limitations |

|---|---|---|---|

| Cordless Drill | Battery | DIY, wood, light metal | Limited runtime |

| Corded Drill | Electric | Continuous heavy work | Less portable |

| Hammer Drill | Electric/Battery | Concrete, brick | Not for fine work |

| Rotary Hammer | Electric | Large concrete holes | Heavy & expensive |

| Impact Driver | Battery | Screws & bolts | Poor for drilling |

| Drill Press | Electric | Precision drilling | Not portable |

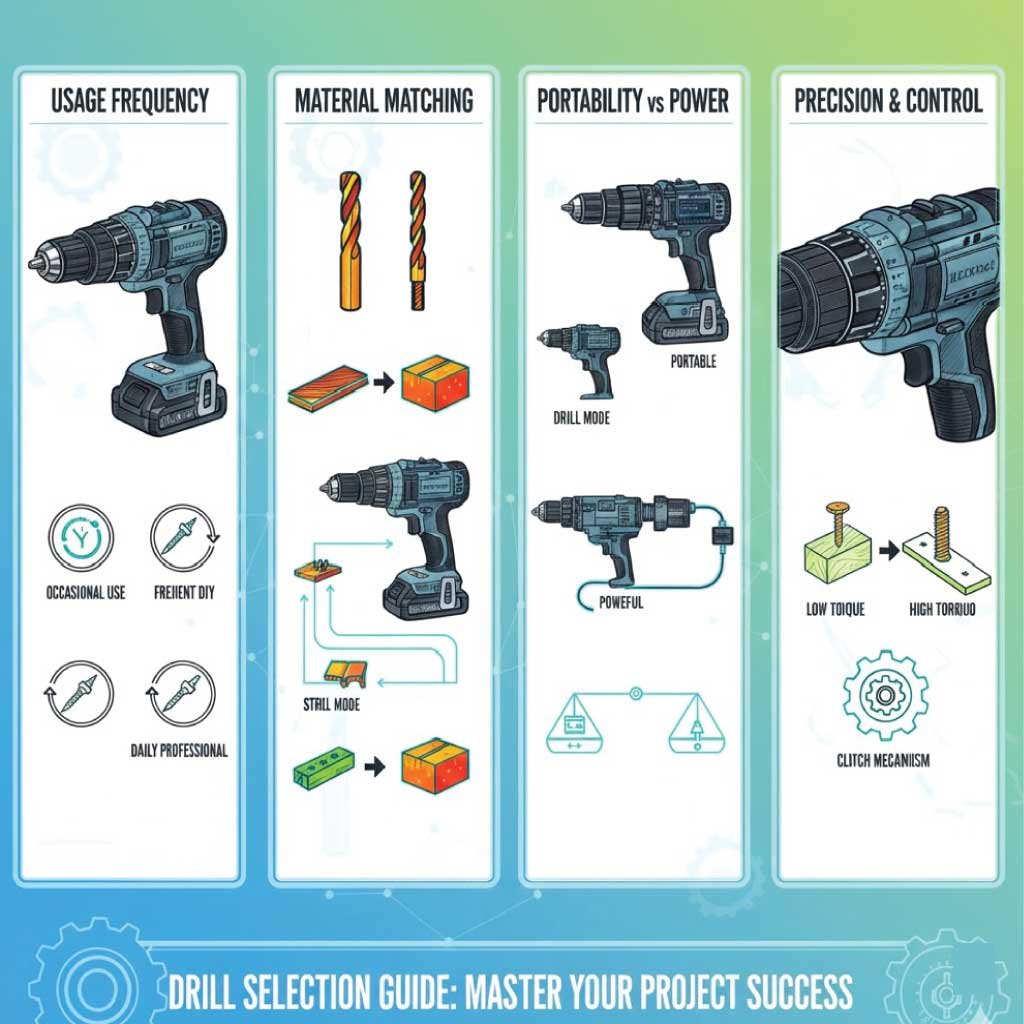

Drill Power, Speed & Torque Explained

Choosing the right drill isn’t only about type—it also depends on power, speed, and torque. These factors control how efficiently a drill works on different materials. Understanding drill power helps you handle tough tasks, speed affects precision, and torque determines how well the drill drives screws without damaging materials.

Voltage (Cordless Drills)

- 12V – Light DIY and household tasks

- 18V / 20V – Most common, balanced performance

- 24V+ – Heavy-duty and professional use

Speed Control

Most drills feature variable speed triggers and two gear settings:

- Low speed for screw driving and hard materials

- High speed for drilling wood and plastic

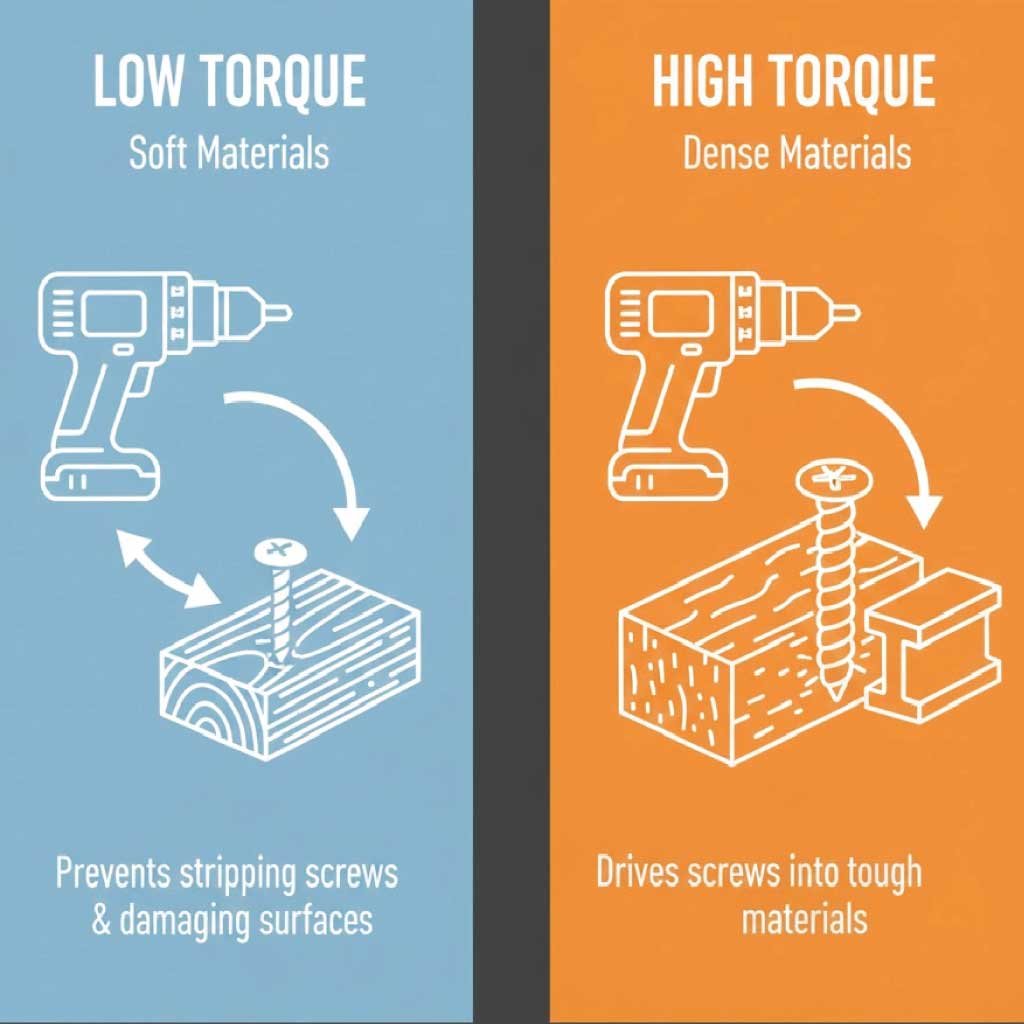

Torque Control

Torque settings prevent over-tightening screws and damaging surfaces. Lower torque is used for soft materials, while higher torque is required for dense materials.

Common Drill Mistakes People Make

Many drilling problems happen because of simple errors. These include using the wrong drill type, applying excessive pressure, or selecting an incorrect speed setting. Another common mistake is using dull or damaged drill bits, which leads to rough holes and overheating.

Proper technique and the right accessories can greatly improve results and tool lifespan.

What Is a Drill Bit?

A drill bit is a cutting tool that attaches to a drill and creates holes by rotating at high speed. Drill bits come in different shapes, tip designs, and materials, each designed to cut a specific surface efficiently.

A good drill bit should:

- Cut cleanly without tearing or cracking the material

- Stay sharp under heat and pressure

- Match the material being drilled

Using the wrong bit often leads to poor results, even if you’re using a powerful drill.

Drill Bit Types Based on Material Use

Instead of memorizing dozens of drill bit names, it’s more practical to focus on their purpose. Understanding what each bit is designed to drill—whether wood, metal, masonry, or specialty materials—makes selecting the right tool faster, reduces mistakes, and ensures cleaner, more efficient, and precise drilling results for any project.

1- Wood Drill Bits

Wood drill bits are specially designed to create clean, precise holes in wood without splintering or tearing the surface. Choosing the right wood bit ensures smooth cuts, accurate placement, and minimal damage to the material. They come in various shapes and sizes, each suited for different woodworking tasks—from furniture assembly to rough carpentry—making them essential for both DIY enthusiasts and professional woodworkers.

2- Twist Drill Bits (Wood & General Use)

Twist drill bits are the most common drill bits and are often included in basic drill sets. While they can work on wood, plastic, and light metal, they are not specialized for fine woodworking. They are ideal for general-purpose drilling where precision isn’t critical.

They work best for:

-

Softwood and hardwood

-

Plywood and MDF

-

General-purpose drilling

3- Brad Point Drill Bits (Clean Wood Holes)

Brad point bits are specifically designed for woodworking. They feature a sharp center point that prevents the bit from wandering and produces clean, accurate holes. These bits are perfect for precision tasks where entry and exit holes must be neat. They are commonly used in cabinetry, furniture making, and fine woodworking but are unsuitable for metal or masonry.

They are ideal when:

-

Precision is important

-

You want clean entry and exit holes

-

Working with furniture or cabinetry

4- Spade Bits (Large Holes in Wood)

Spade bits have a flat, wide design, making them perfect for drilling large holes quickly. They are less precise than brad point bits but excel in speed and rough carpentry applications. Spade bits are commonly used in electrical, plumbing, or construction tasks where clean finishes aren’t essential. They require careful control to prevent splintering and rough edges.

Common uses include:

-

Electrical wiring holes

-

Plumbing pass-throughs

-

Rough carpentry

5- Auger Bits (Deep, Clean Holes)

Auger bits are long, screw-tipped wood bits designed to pull themselves through thick wood with minimal effort. They produce clean, deep holes ideal for structural or heavy-duty woodworking. Auger bits work best with powerful drills and require steady control to ensure accuracy, making them popular in construction framing and large timber projects.

They are used for:

-

Deep holes in wood

-

Thick beams and posts

-

Construction framing

6- Metal Drill Bits

Drilling metal requires bits that can handle heat and resist wear. Metal drill bits are typically made of high-speed steel, cobalt, or coated with titanium to improve durability. Selecting the right type ensures efficiency, reduces bit breakage, and prevents overheating. Metal bits can also work on plastics and other hard materials, depending on their design.

7- High-Speed Steel (HSS) Bits

HSS drill bits are versatile and commonly used for light to medium metalwork. They can withstand higher temperatures than standard steel bits, making them suitable for continuous drilling. HSS bits are also useful for wood and plastic, providing a general-purpose solution for home workshops or DIY projects.

They work well for:

-

Aluminum

-

Copper

-

Brass

-

Thin steel

8- Cobalt Drill Bits (Hard Metals)

Cobalt drill bits are an upgraded version of HSS bits, containing a higher percentage of cobalt alloy for extreme durability. They resist heat and wear, making them ideal for demanding metalwork and professional use. These bits are specifically designed to handle hard metals without dulling quickly.

Best for:

-

Stainless steel

-

Cast iron

-

Hardened metals

9- Titanium-Coated Drill Bits

Titanium-coated bits are HSS bits with a titanium nitride layer that reduces friction and prolongs bit life. They are ideal for light metal, wood, and plastic work. However, once the coating wears off, the bit behaves like a standard HSS bit, so careful use is recommended to maintain performance.

They are suitable for:

-

Light metal work

-

Plastic

-

Wood

10- Masonry Drill Bits

Masonry materials such as brick, concrete, and stone require impact-resistant drill bits. Masonry bits have carbide tips that crush materials rather than cut, making them suitable for hammer drills. Using the correct bit ensures faster, cleaner holes and prevents damage to both the tool and the surface.

11- Standard Masonry Bits

Standard masonry bits feature a carbide tip that can withstand hammering into hard surfaces. They are essential for home construction or DIY masonry projects where concrete, brick, stone, or block walls are involved. These bits work best when paired with a hammer drill for efficient drilling.

Used for:

-

Concrete

-

Brick

-

Stone

-

Block walls

12- SDS Drill Bits (Rotary Hammer Use)

SDS drill bits are designed for rotary hammer drills, offering superior impact performance and secure chuck fitting. They excel at heavy-duty drilling in concrete or masonry and are standard in professional construction. SDS bits are not compatible with standard drills, making them specialized tools for large-scale projects.

They are used for:

-

Large concrete holes

-

Heavy construction work

-

Professional masonry projects

13- Specialty Drill Bits

Some drilling tasks require unique solutions beyond standard bits. Specialty drill bits include step bits, hole saws, and countersink bits, each designed for specific materials or precise tasks. Using the right specialty bit ensures efficiency, accuracy, and clean results in challenging or specialized applications.

14- Step Drill Bits

Step bits are cone-shaped bits capable of drilling multiple hole sizes with one tool. They provide smooth, burr-free holes and are excellent for sheet metal, electrical panels, and thin plastics. Step bits save time and improve precision when multiple hole diameters are needed in the same material.

Common uses:

-

Sheet metal

-

Electrical panels

-

Thin plastic

15- Hole Saw Bits

Hole saw bits use a toothed circular ring to create large-diameter holes quickly. They are suitable for woodworking, metal, and multi-material applications. These bits are commonly used for installing doors, plumbing, electrical boxes, and ducts where large, clean openings are required.

Used for:

-

Door hardware

-

Pipes and ducts

-

Electrical boxes

16- Countersink Bits

Countersink bits allow screws to sit flush with or below the surface, giving a neat, professional finish. They are primarily used in woodworking and furniture assembly. Countersink bits prevent wood from splitting and ensure smooth surfaces for painting or staining, improving both functionality and aesthetics.

Drill Bit Material Comparison Table

This drill bit material comparison table helps you quickly identify the best bit for your project. It highlights which materials each bit is suited for, their durability, and heat resistance. Using the right bit material ensures cleaner holes, longer tool life, and safer, more efficient drilling for wood, metal, or masonry.

| Bit Material | Best For | Durability | Heat Resistance |

|---|---|---|---|

| Carbon Steel | Wood only | Low | Low |

| HSS | Wood & light metal | Medium | Medium |

| Titanium-Coated | General use | Medium–High | Medium |

| Cobalt | Hard metals | High | Very High |

| Carbide-Tipped | Masonry | Very High | Extremely High |

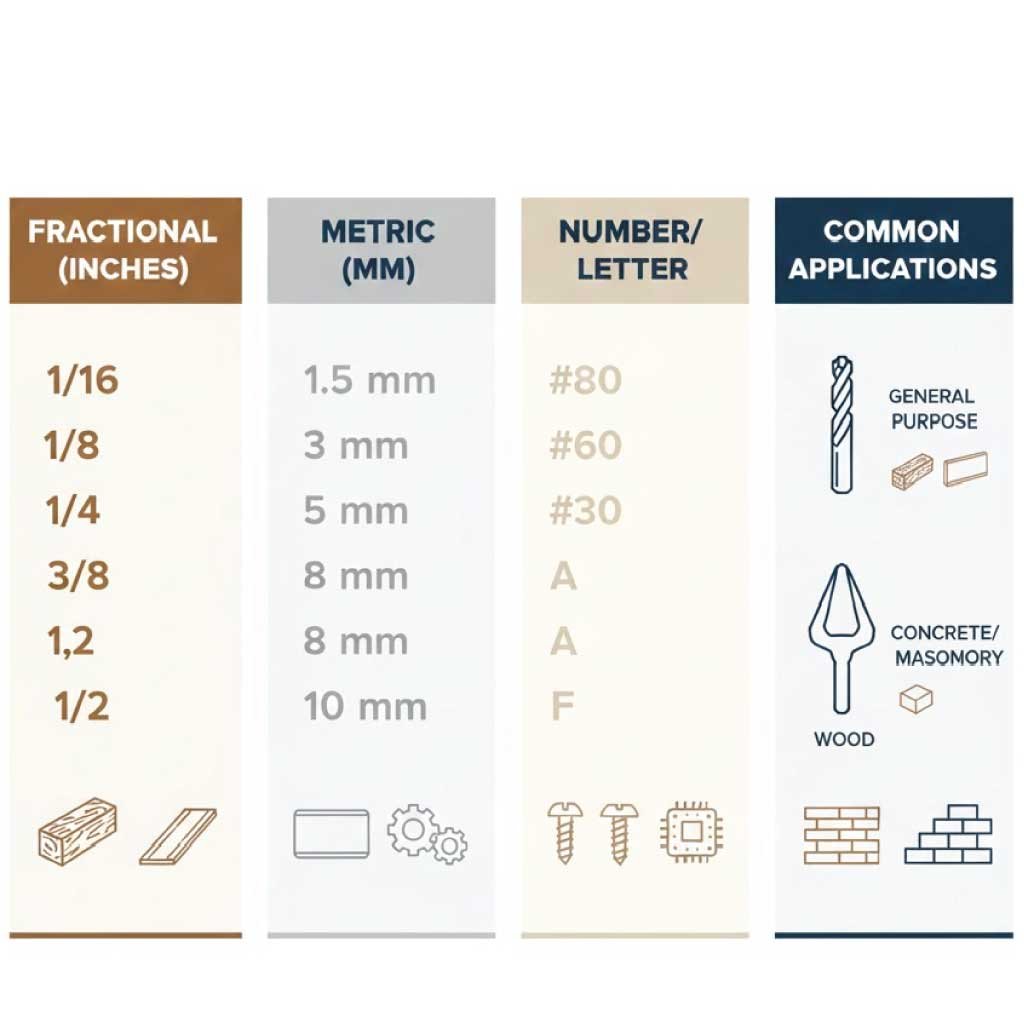

Fractional vs Metric Drill Bit Conversion Chart

This conversion chart makes it easy to match inch-sized drill bits with their metric equivalents. It’s especially useful when following instructions or projects that use a different measurement system than your available drill bits, ensuring accurate hole sizes and preventing mistakes during drilling.

| Inch Size | Metric Equivalent (mm) |

|---|---|

| 1/16″ | 1.59 mm |

| 1/8″ | 3.18 mm |

| 3/16″ | 4.76 mm |

| 1/4″ | 6.35 mm |

| 5/16″ | 7.94 mm |

| 3/8″ | 9.53 mm |

| 1/2″ | 12.70 mm |

This chart is helpful when instructions are written in a different measurement system than your drill bits.

Choosing the Correct Drill Bit Size for Screws

One common mistake is drilling holes that are too large or too small for screws, which can lead to loose or damaged fittings. To avoid this, match the drill bit size to the screw’s core (shaft) rather than the threads, ensuring a secure fit and strong, stable connections.

Pilot Hole Size Guide (Wood Screws)

| Screw Size | Recommended Bit Size |

|---|---|

| #4 | 3/32″ |

| #6 | 7/64″ |

| #8 | 1/8″ |

| #10 | 9/64″ |

| #12 | 5/32″ |

Pilot holes reduce wood splitting and make screw driving easier.

Drill Bit Sizes for Wall Anchors

When installing wall anchors, it’s crucial to match the hole size to the anchor. A hole that’s too large prevents the anchor from gripping properly, while a hole that’s too small makes insertion difficult or impossible. Always refer to the anchor packaging, but the following general guide provides useful sizing tips.

| Anchor Size | Drill Bit Size |

|---|---|

| Small plastic anchor | 3/16″ |

| Medium plastic anchor | 1/4″ |

| Large plastic anchor | 5/16″ |

| Masonry anchor | Exact anchor diameter |

For concrete and brick, always use masonry drill bits and a hammer drill.

How Deep Should You Drill?

Hole depth matters just as much as width. A hole that’s too shallow can prevent screws or anchors from seating properly.

A simple trick is to mark the required depth on your drill bit using tape. This helps you stop drilling at the right point without guessing.

Drill Speed Guide by Material

Using the correct speed improves accuracy and extends drill bit life.

| Material | Recommended Speed |

|---|---|

| Wood | High speed |

| Plastic | Medium speed |

| Aluminum | Medium speed |

| Steel | Low speed |

| Stainless steel | Very low speed |

| Concrete | Medium speed (hammer mode) |

Lower speeds reduce heat buildup, especially in metal drilling.

Step-by-Step Guide to Drilling Clean Holes

Drilling clean holes requires proper technique, not excessive force. Using the right drill bit, correct speed, and controlled pressure ensures smooth, precise holes. Following best practices prevents damage to the workpiece, reduces bit wear, and improves overall drilling efficiency, whether working with wood, metal, or masonry.

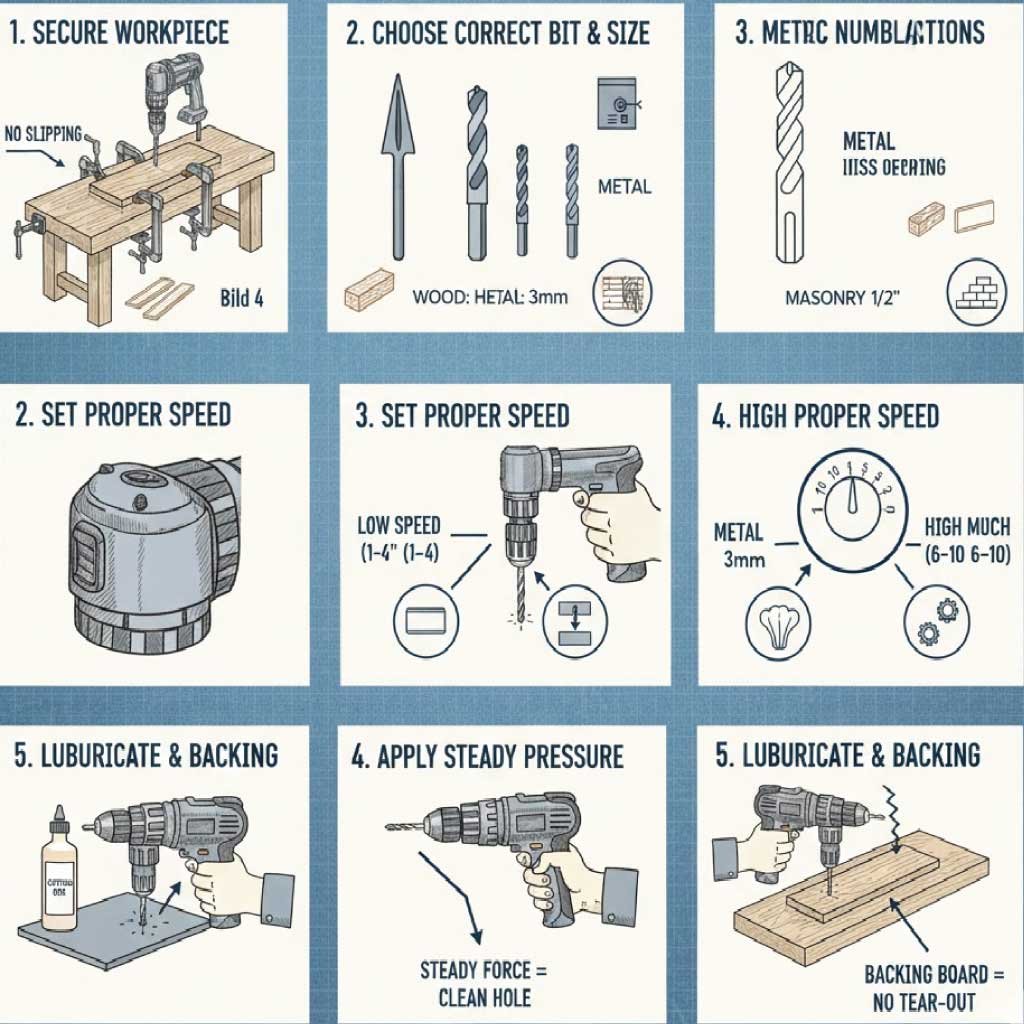

1. Secure the Workpiece Firmly

Before drilling, ensure the material is clamped or held securely. A stable workpiece prevents slipping, uneven holes, and potential accidents. Proper support also reduces vibration, allowing the drill bit to cut smoothly and maintain accuracy throughout the drilling process.

2. Choose the Correct Drill Bit and Size

Selecting the right drill bit and size is crucial for clean holes. Match the bit to the material and hole requirements. Using an incorrect bit can cause splintering, overheating, or damage to both the bit and the workpiece.

3. Set the Proper Speed

Adjust the drill speed according to the material. High speeds work for softwood or plastic, while slower speeds are better for metal or hard materials. Proper speed reduces heat buildup, prevents bit dulling, and ensures a smooth, precise cut.

4. Apply Steady, Controlled Pressure

Apply even pressure while drilling; forcing the bit can cause wandering, breakage, or rough edges. Let the bit do the cutting. Controlled pressure ensures cleaner holes, protects the drill bit, and maintains accuracy throughout the process.

5. Use Lubrication and Backing Techniques

For metal, use cutting oil to reduce heat and extend bit life. For wood, place a backing board to prevent tear-out on exit. These simple techniques improve hole quality and prevent damage to both material and drill bit.

Safety Tips When Using Drills and Drill Bits

Safety is essential whenever using drills, regardless of project size. Following simple precautions protects you from accidents and injuries while ensuring smooth, efficient work. Proper handling, protective gear, and awareness of surroundings make drilling safer for both beginners and experienced users.

Always:

-

Wear safety glasses

-

Keep loose clothing away

-

Hold the drill with both hands

-

Unplug or remove the battery before changing bits

Maintaining Drill Bits for Long-Term Use

Proper maintenance keeps drill bits sharp, safe, and efficient for years. Regular care prevents damage, reduces wear, and ensures precise drilling. By following simple habits, you can extend bit life, maintain performance, and save money by avoiding frequent replacements.

To extend bit life:

-

Clean bits after use

-

Store them in labeled cases

-

Avoid overheating

-

Sharpen metal bits when dull

Final Thoughts: Choosing the Right Drill & Drill Bit Every Time

Drills and drill bits are not one-size-fits-all tools. The best results come from understanding what you’re drilling, which drill to use, and which bit size fits the job.

Whether you’re drilling wood, metal, or concrete, the right combination of drill type, drill bit material, and size ensures clean holes, stronger fastenings, and safer work.

This complete drill and drill bit guide is designed to be your go-to reference—whether you’re a beginner learning the basics or an experienced user refining your technique.