Fasteners play a critical role in mechanical, construction, and industrial applications. Among them, lock nuts are specially designed to prevent loosening caused by vibration, torque, or movement.

Whether used in machinery, automotive systems, or structural assemblies, lock nuts provide extra safety and reliability where standard nuts may fail.

In this guide, you will learn what a lock nut is, how it works, its types, materials, applications, and advantages, along with easy-to-understand tables for quick reference.

What Is a Lock Nut?

A lock nut is a specialized nut designed to resist loosening under vibration or rotational forces. Unlike standard nuts, it relies on mechanical locking features or friction to stay securely in place once tightened, making it ideal for machinery, automotive assemblies, and structural applications where stability is critical.

They are commonly used in:

- Heavy machinery

- Automotive assemblies

- Structural steel connections

- Electrical and industrial equipment

Lock nuts are essential where safety, stability, and long-term fastening strength are required.

What Does a Lock Nut Look Like?

A lock nut looks similar to a regular hex nut, but it has a built-in feature that prevents it from loosening under vibration or movement. The exact appearance depends on the type of lock nut.

The most common type is the nylon insert lock nut (Nyloc). It looks like a standard hex nut with a nylon ring visible at one end. This nylon insert is usually white or blue and is easy to spot. When tightened, the bolt passes through the nylon, creating friction that locks the nut in place.

An all-metal lock nut looks like a normal hex nut, but one end may appear slightly oval or distorted. This deformation is intentional and creates resistance on the bolt threads.

A serrated flange lock nut has a wide, washer-like base with teeth on the underside. These teeth grip the surface to prevent rotation.

Overall, if a nut has a nylon ring, deformed threads, or serrated base, it’s likely a lock nut.

How Does a Lock Nut Work?

A lock nut secures a bolt by creating additional resistance between the nut and bolt threads. This resistance can be achieved through deformed threads, nylon inserts, serrated surfaces, or jam nut techniques, ensuring the nut stays firmly in place even under vibration, movement, or heavy loads.

- Deformed threads

- Nylon inserts

- Toothed or serrated surfaces

- Jam nut techniques

By increasing friction or mechanically locking against the bolt, the nut stays secure even under constant vibration or load changes.

Lock Nut Orientation: Which Side and How to Install

A lock nut should always be installed in a way that allows its locking feature to engage last when tightening. This ensures maximum resistance against loosening. The exact orientation depends on the type of lock nut being used, so identifying the nut style is the first step before installation.

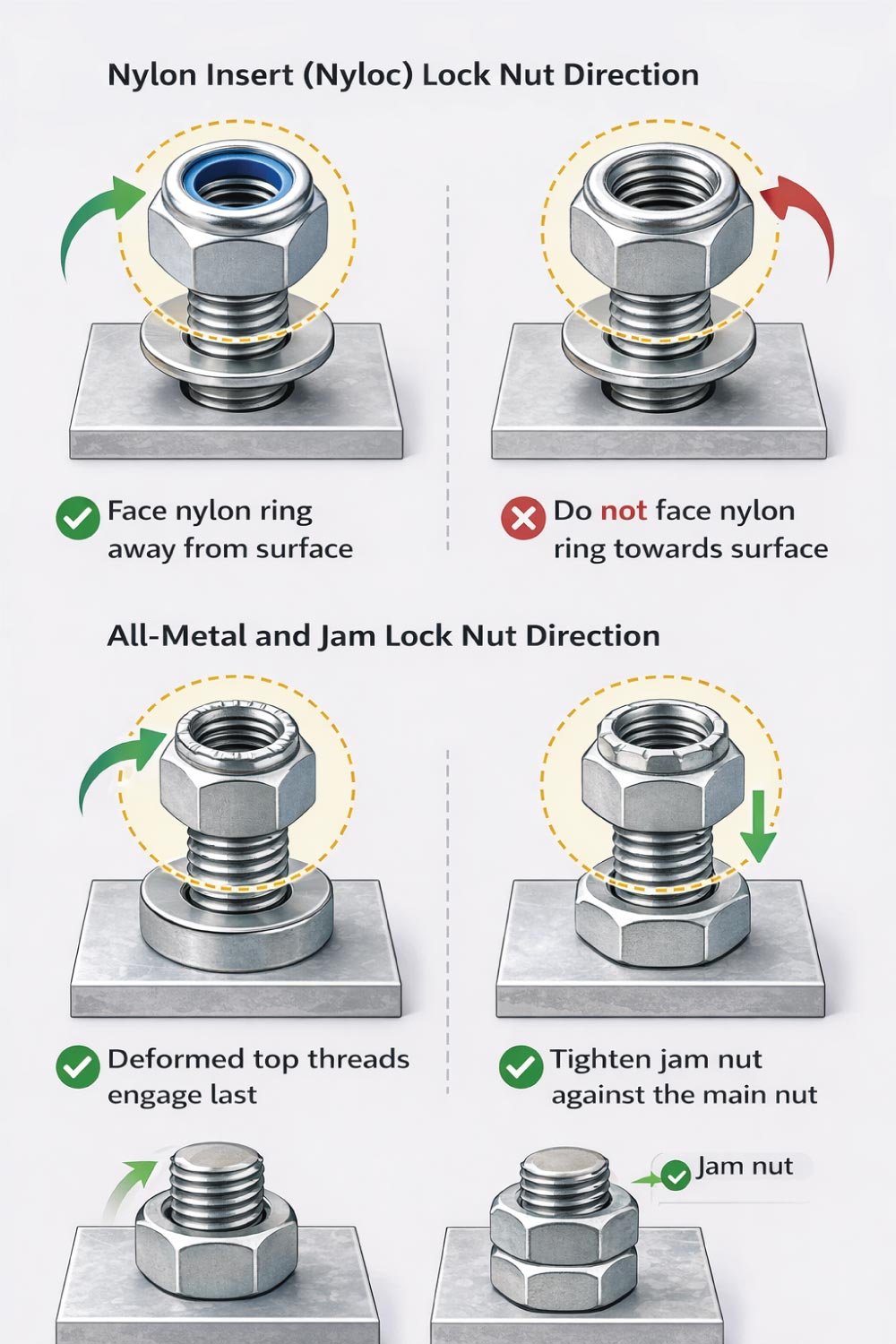

1- Nylon Insert (Nyloc) Lock Nut Direction

For a nylon insert lock nut, the nut goes on with the nylon ring facing away from the surface being fastened. The metal threads should engage first, and the bolt should pass through the nylon insert at the end. This allows the nylon to grip the bolt threads tightly, creating friction that prevents the nut from backing off due to vibration.

2- All-Metal and Jam Lock Nut Direction

With all-metal lock nuts, the deformed or locking threads are typically positioned at the top of the nut, meaning they engage last during tightening. Jam nuts are installed by tightening the thinner nut against the main nut, locking both in place. Correct orientation ensures strength, safety, and long-term fastening reliability.

Types of Lock Nuts (With Table)

Lock nuts come in various types, each tailored for specific applications. Selecting the right lock nut depends on factors such as load capacity, operating temperature, vibration levels, and whether it needs to be reusable, ensuring secure and reliable fastening in any environment.

Table: Types of Lock Nuts and Their Features

| Lock Nut Type | Key Feature | Best Used For |

|---|---|---|

| Nylon Insert Lock Nut (Nyloc) | Nylon ring grips threads | Automotive, light machinery |

| All-Metal Lock Nut | Deformed metal threads | High-temperature applications |

| Jam Nut | Thin nut tightened against main nut | Adjustable assemblies |

| Serrated Flange Lock Nut | Built-in washer with teeth | Structural and machinery use |

| Castle Nut (with cotter pin) | Slotted nut with pin | Axles, wheel assemblies |

Materials Used in Lock Nuts

Lock nuts are made from a variety of materials to meet different load, environmental, and application requirements. Common materials include carbon steel, stainless steel, alloy steel, brass, and nylon inserts, each chosen for its strength, corrosion resistance, and suitability for specific operating conditions.

Table: Lock Nut Materials and Properties

| Material | Strength Level | Corrosion Resistance | Common Applications |

|---|---|---|---|

| Carbon Steel | High | Low | Construction, machinery |

| Stainless Steel | Medium–High | Excellent | Marine, outdoor use |

| Alloy Steel | Very High | Medium | Heavy-duty equipment |

| Brass | Low–Medium | Good | Electrical fittings |

| Nylon (Insert only) | Not load-bearing | N/A | Vibration resistance |

Material selection is critical, especially in environments exposed to moisture, heat, or chemicals.

Lock Nut Sizes and Thread Standards

Lock nuts are available in metric (ISO) and imperial (UNC/UNF) thread standards. Common sizes range from M3 to M64 in metric and ¼ inch to 2 inches in imperial measurements.

Table : Common Lock Nut Sizes and Applications

| Size Range | Thread Standard | Typical Use |

|---|---|---|

| M3 – M6 | Metric (ISO) | Electronics, light assemblies |

| M8 – M16 | Metric (ISO) | Automotive, machinery |

| M20 – M36 | Metric (ISO) | Structural steel, heavy equipment |

| ¼” – ½” | UNC/UNF | General-purpose fastening |

| ¾” – 2″ | UNC/UNF | Industrial and construction use |

Discover More:

👉 Discover the ultimate Nut Size Chart covering all types, materials, and applications. Whether you are working with lock nuts, hex nuts, or industrial fasteners, this guide helps you choose the right nut for your project. Read the full post to ensure perfect fastening every time!

Advantages of Using Lock Nuts

Lock nuts provide enhanced performance over standard nuts, making them ideal for high-vibration or heavy-duty applications. Their unique design ensures a secure hold, improves safety, and reduces maintenance. These features make lock nuts a reliable choice for both industrial and mechanical assemblies.

- Prevents loosening due to vibration

- Improves safety and structural integrity

- Reduces maintenance and retightening

- Available in reusable and permanent options

- Works with standard bolts and studs

These benefits make lock nuts a preferred choice in critical assemblies.

Disadvantages to Consider

Although lock nuts provide excellent security and reliability, they do have some limitations. Certain types may lose effectiveness under high temperatures, are not reusable, cost more than standard nuts, or require extra torque during installation. Knowing these helps in choosing the right lock nut for your application.

- Nylon insert lock nuts may lose effectiveness at high temperatures

- Some types are not reusable

- Higher cost compared to standard nuts

- May require more torque to install

Understanding these limitations helps in selecting the correct type.

Lock Nut Installation and Use

Start by selecting the correct lock nut size and type for your bolt and application. Make sure the bolt threads are clean and undamaged, as dirt or worn threads can reduce the locking effect. Hand-thread the lock nut onto the bolt to ensure it engages smoothly and does not cross-thread.

1- Install the Lock Nut Properly

Thread the lock nut onto the bolt in the correct direction, depending on the type. For nylon insert lock nuts, the nylon ring should engage last while tightening. Use a wrench or socket to tighten the nut until it is fully seated against the surface. Avoid over-tightening, especially with nylon insert nuts, as excessive torque can damage the locking feature.

2- Check Tightness and Reusability

After installation, ensure the lock nut is firmly secured and does not rotate freely. In vibration-prone applications, recheck the nut after initial use. Remember that some lock nuts, particularly nylon insert types, may lose effectiveness after repeated use and should be replaced when their locking resistance feels weak.

👉 Explore the complete Heavy Hex Nut Guide, including definition, dimensions, sizes, and materials. Learn how these high-strength nuts are used in construction, machinery, and industrial applications. Read the full post to choose the right heavy hex nut for your project with confidence!

Lock Nut vs Standard Nut

A standard nut relies only on tightening torque to stay in place, while a lock nut includes an additional locking mechanism. In high-vibration environments, standard nuts can loosen over time, whereas lock nuts maintain their grip.

Lock nuts are recommended when:

- Vibration is constant

- Safety is critical

- Retightening is difficult or costly

Which Side of the Lock Nut Goes On First?

Before installing a lock nut, it’s important to understand its correct orientation. The side with the locking feature should engage last to ensure a secure fit. Proper installation depends on the type—nylon insert, all-metal, or serrated flange—to prevent loosening under vibration.

1- Identify the Locking Feature

Before installation, look closely at the lock nut to find its locking element. This could be a nylon insert, deformed threads, serrations, or a thinner jam profile. The general rule is simple: the non-locking side goes on first, and the locking feature engages last to hold the nut firmly in place.

2- Nylon Insert Lock Nut Orientation

For a nylon insert (Nyloc) lock nut, the metal-threaded side goes on first. The nylon insert should be on the outer side of the joint so the bolt passes through it at the end of tightening. This allows the nylon ring to grip the threads tightly and prevent loosening due to vibration.

3- All-Metal and Serrated Lock Nuts

With all-metal lock nuts, the rounder or less deformed threads go on first, while the deformed locking threads engage last. Serrated flange lock nuts are installed with the serrated flange facing the material surface to bite into it, ensuring a secure and vibration-resistant connection.

👉 Check out the ultimate Hex Nut Sizes guide, covering dimensions, grades, and how to measure. Whether for mechanical, automotive, or industrial projects, this post helps you select the right hex nut for perfect fit and secure fastening. Read the full guide now!

Which Way Does a Lock Nut Go On a Bolt

A lock nut should go onto a bolt so that its locking feature engages last during tightening. In simple terms, the non-locking side goes on first, and the locking side works at the end to hold everything tight.

For a nylon insert (Nyloc) lock nut, the nut goes on with the metal threads first. The nylon insert faces outward, away from the joint. As you tighten, the bolt passes through the nylon ring last, creating friction that prevents the nut from loosening due to vibration.

For all-metal lock nuts, install the nut so the smooth or rounder threads engage first, and the deformed locking threads engage last. This ensures the nut locks securely once fully tightened.

With serrated flange lock nuts, the serrated flange faces the surface being fastened to grip the material and resist movement.

Following the correct orientation ensures maximum holding power, safety, and long-term reliability.

How to Tighten a Lock Nut Correctly

Tightening a lock nut properly ensures a secure and long-lasting connection. Start by hand-threading, then use the correct tool to apply steady pressure, and finish with the recommended torque. Proper technique prevents damage to the nut, bolt, or locking feature, especially in high-vibration applications.

1- Start by Hand-Threading

Place the lock nut onto the bolt with the non-locking side first. Turn it by hand for a few threads to make sure it goes on smoothly and does not cross-thread. This step is important for protecting both the bolt and the locking feature of the nut.

2- Tighten with the Proper Tool

Use the correct wrench or socket for the nut size. Tighten the lock nut until it sits firmly against the surface. You will feel increased resistance once the locking feature (nylon insert or deformed threads) engages—this is normal. Do not force it suddenly; apply steady, even pressure.

3- Apply Correct Torque and Final Check

If torque specifications are available, use a torque wrench to reach the recommended value. Avoid over-tightening, especially with nylon insert lock nuts, as this can damage the locking element. After tightening, check that the nut does not spin freely and remains secure, particularly in vibration-prone applications.

How to Choose the Right Lock Nut

Choosing the right lock nut is essential for secure and reliable fastening. Consider factors such as vibration, temperature, load, environment, and reusability. Selecting a lock nut suited to the application ensures optimal performance, long-term durability, and prevents loosening in demanding conditions.

- Vibration level – High vibration needs stronger locking

- Temperature – Avoid nylon inserts in high heat

- Load requirement – Choose high-strength materials

- Environment – Corrosion resistance may be required

- Reusability – All-metal types are often reusable

Matching the lock nut to the application ensures long-lasting performance.

Final Thoughts

A lock nut is a small but essential fastener that plays a major role in safety and reliability. With various types, materials, and sizes available, lock nuts are suitable for everything from light electronics to heavy industrial machinery.

By understanding how lock nuts work and where to use them, you can prevent loosening, reduce maintenance costs, and improve overall system performance. Always choose the correct lock nut type based on your application’s vibration, load, and environmental conditions.