Nylon insert lock nuts are small yet incredibly important components in mechanical assemblies. They might look simple, but their role in securing bolts and preventing loosening due to vibrations or torque is crucial.

In this guide, we will explore everything you need to know about nylon insert lock nuts, including how to use them, their dimensions, and torque specifications.

Whether you are a DIY enthusiast, engineer, or mechanic, this guide will give you all the details you need.

What Is a Nylon Insert Lock Nut?

A nylon insert lock nut, also known as a nyloc nut, is a type of lock nut that includes a nylon collar insert. This insert increases friction on the bolt threads, which prevents the nut from loosening under vibration or torque. Unlike standard nuts, nylon insert lock nuts offer a reusable and reliable solution for keeping fasteners secure in applications ranging from automotive to industrial machinery.

These nuts are particularly popular because they do not require washers or adhesives to maintain their grip. The nylon insert acts as a self-locking mechanism, which makes them efficient and easy to use in a wide variety of projects.

Nylon Insert Lock Nut Dimensions

Understanding nylon insert lock nut dimensions is important when selecting the right nut for your project. The dimensions include the nut width across flats, height, thread diameter, and the internal nylon collar size. Choosing the correct dimensions ensures proper fit and function.

Here’s a sample dimensions table for commonly used nylon insert lock nuts:

| Thread Size (mm) | Width Across Flats (mm) | Height (mm) | Nylon Insert Thickness (mm) |

|---|---|---|---|

| M4 | 7 | 4 | 1 |

| M5 | 8 | 5 | 1.5 |

| M6 | 10 | 6 | 1.5 |

| M8 | 13 | 8 | 2 |

| M10 | 17 | 10 | 2.5 |

| M12 | 19 | 12 | 3 |

Note: Dimensions may vary slightly depending on standards (ISO, DIN, ANSI).

Nylon Insert Lock Nut How to Use

If you’re wondering “nylon insert lock nut how to use” or “how to use nylon insert lock nut”, the process is straightforward. Simply select the correct size, thread the nut onto the bolt by hand, then tighten with a wrench. Following proper torque ensures secure, reliable fastening every time.

Steps to Use a Nylon Insert Lock Nut:

1- Select the Correct Size

Choosing the right nut is crucial for a secure fit. Match the nylon insert lock nut to the bolt or threaded rod, ensuring proper alignment. If you’re unsure, refer to the nylon insert lock nut size chart. Using the correct size prevents thread damage and ensures reliable fastening in any application.

2- Thread the Nut by Hand

Begin by threading the nylon insert lock nut onto the bolt manually. Take care to align it properly to avoid cross-threading, which can damage both nut and bolt. Hand-threading first ensures smooth installation and helps the nylon insert engage correctly, giving the nut its locking functionality and long-lasting hold.

3- Tighten with a Wrench

After hand-threading, use a spanner or socket wrench to tighten the nylon insert lock nut. The nylon insert adds friction that resists loosening under vibration. Tighten steadily without forcing it, ensuring the nut seats properly. This step is key for maintaining the nut’s locking capability and keeping your assembly secure.

4- Check Torque

For critical applications, use a torque wrench to apply the correct force to the nylon insert lock nut. Over- or under-tightening can reduce its effectiveness. Refer to the nylon insert lock nut torque chart for recommended torque values to ensure optimal performance, secure fastening, and the nut’s longevity.

👉 Discover the ultimate Lock Nut Guide! Learn about different types of lock nuts, their uses, key benefits, and step-by-step instructions on how to install them correctly. This comprehensive guide helps both DIY enthusiasts and professionals ensure secure, reliable fastening. Read the full post to master every detail!

How to Remove a Nylon Insert Lock Nut

Sometimes, you will need to remove a nylon insert lock nut. Although these nuts are designed to resist loosening, proper removal is simple. Use the correct wrench size, turn the nut counterclockwise steadily, and avoid sudden force. For stubborn nuts, gentle heating can soften the nylon insert, making removal easier and preventing thread damage.

1- Use the Correct Wrench Size

Always choose the right wrench or socket for the nylon insert lock nut. Using the wrong size can round off the nut corners, making removal difficult and damaging threads. A properly sized tool ensures smooth, safe removal and preserves both the nut and the bolt for future use.

2- Apply Steady Pressure

Turn the nylon insert lock nut counterclockwise steadily to loosen it. Avoid sudden jerks or excessive force, which can strip threads or damage the nut. Applying consistent pressure helps the nylon insert release gradually while keeping the bolt and surrounding components intact.

3- Heat if Necessary

For stubborn or tightly fastened nuts, gently heat the area around the nylon insert lock nut. This softens the nylon insert slightly, making it easier to loosen without forcing the nut. Be careful not to overheat, as excessive heat can damage surrounding materials or the nut itself.

4- Inspect After Removal

Once removed, check the nylon insert lock nut for wear or damage. If the nylon insert is deformed or compromised, replace the nut before reuse. Inspecting ensures that future assemblies remain secure and that the locking functionality of the nut is maintained for safe, reliable fastening.

👉 Explore the complete Heavy Hex Nut Guide! Learn the definition, understand dimensions and sizes, and discover the materials used for heavy hex nuts. This detailed guide helps you choose the right nut for your project and ensures proper installation and secure fastening. Read the full post now!

Nylon Insert Lock Nut Size Chart

Choosing the right nut size is critical for the effectiveness of nylon insert lock nuts. Here’s a size chart for common metric sizes:

| Bolt Size (mm) | Nut Size (mm) | Recommended Torque (Nm) |

|---|---|---|

| M4 | 7 | 3–4 |

| M5 | 8 | 5–6 |

| M6 | 10 | 10–12 |

| M8 | 13 | 20–25 |

| M10 | 17 | 40–45 |

| M12 | 19 | 70–75 |

Tip: Always check the manufacturer’s recommendations for torque limits, as excessive torque can damage the nylon insert.

Nylon Insert Lock Nut Torque Chart

The torque applied to a nylon insert lock nut is vital for its performance. Over-tightening can damage the nylon, while under-tightening may lead to loosening. Here’s a torque chart to guide you:

| Nut Size (mm) | Recommended Torque (Nm) | Max Torque (Nm) |

|---|---|---|

| M4 | 3–4 | 5 |

| M5 | 5–6 | 8 |

| M6 | 10–12 | 15 |

| M8 | 20–25 | 30 |

| M10 | 40–45 | 55 |

| M12 | 70–75 | 90 |

Note: Torque values may vary depending on materials and application conditions.

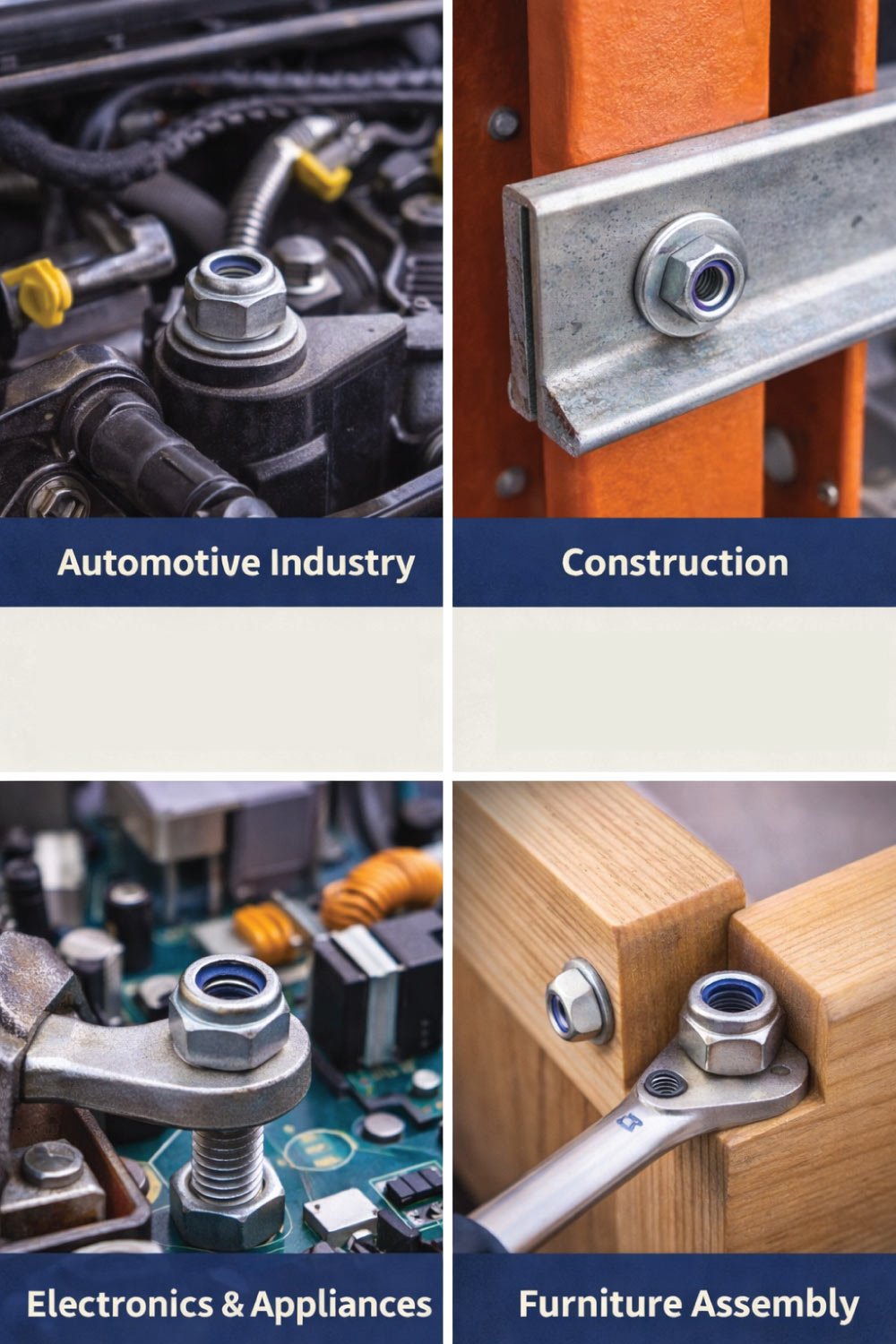

Applications of Nylon Insert Lock Nuts

Nylon insert lock nuts are widely used across industries because they resist loosening under vibration and stress. Their reliability makes them ideal for critical applications. Common uses include securing engine and suspension parts in automotive, fastening structural elements in construction, holding delicate components in electronics, and ensuring stable joints in furniture assembly.

1- Automotive Industry

In the automotive industry, nylon insert lock nuts are used to secure engines, suspension systems, and body assemblies. Their vibration-resistant design ensures components stay tight even under constant movement, providing reliable performance and safety in vehicles.

2- Construction

In construction, nylon insert lock nuts are ideal for fastening structural elements and machinery components. They prevent loosening caused by vibrations or heavy loads, ensuring long-lasting stability and secure connections in buildings, bridges, and other structural projects.

3- Electronics and Appliances

For electronics and appliances, nylon insert lock nuts hold delicate components securely in place. Their self-locking feature prevents loosening due to vibration, ensuring sensitive circuits and mechanical parts remain safe and functional in everyday devices.

4- Furniture Assembly

In furniture assembly, nylon insert lock nuts create strong, stable joints in movable furniture and cabinets. They prevent bolts and screws from loosening over time, maintaining the durability, safety, and stability of both home and office furniture.

The versatility and reliability of nylon insert lock nuts make them a go-to choice for both professional and DIY projects.

👉 Check out our complete guide on Hex Nut Sizes, Dimensions, Grades & How to Measure! Learn to identify the right hex nut size, understand dimensions and grades, and master the correct way to measure nuts for secure and reliable fastening. Read the full post for all essential details!

Advantages of Nylon Insert Lock Nuts

Nylon insert lock nuts offer several advantages that make them a preferred choice in many applications. They resist vibration, are reusable, and easy to install with just hand-threading and a wrench. Available in a wide range of sizes, they provide a secure, cost-effective solution for reliable fastening in both metric and imperial systems.

Vibration Resistance: The nylon insert prevents the nut from loosening due to vibrations.

Reusable: Unlike some locking adhesives or chemical solutions, nyloc nuts can be reused multiple times without losing effectiveness.

Easy Installation: Simple hand-threading followed by wrench tightening is all it takes.

Wide Range of Sizes: Available for metric and imperial bolt sizes.

Cost-Effective: Provides a secure locking solution without expensive or complex components.

Tips for Best Results

To get the best performance from nylon insert lock nuts, always match the nut size to the bolt. Avoid over-tightening to protect the nylon insert, and replace worn nuts promptly. For critical applications, use a torque wrench, and store unused nuts in a cool, dry place to keep the nylon durable.

- Always match the nut size to the bolt size.

- Avoid over-tightening, which can damage the nylon insert.

- Replace nuts if the nylon insert shows wear.

- Use a torque wrench for critical applications to ensure proper torque.

- Store unused nuts in a cool, dry place to prevent the nylon from becoming brittle.

👉 Discover the Complete Nut Guide! Learn about different types of nuts, their sizes, common uses, and the materials they are made from. This comprehensive guide helps you select the right nut for any project and ensures proper installation for secure, long-lasting fastening. Read the full post now!

Common Mistakes to Avoid

When using nylon insert lock nuts, avoid common mistakes that can compromise performance. Using the wrong size may strip threads, while over-tightening can deform the nylon insert. Reusing old or worn nuts reduces effectiveness, and ignoring torque specifications can lead to loosening or failure. Always follow proper guidelines for secure fastening.

Using the Wrong Size: A mismatched nut can strip the threads or fail to lock.

Over-Tightening: Excess torque can deform the nylon insert, reducing effectiveness.

Reusing Old Nuts: Nylon inserts wear over time. Always inspect before reuse.

Ignoring Torque Specifications: Always follow the torque chart for safe and effective use.

Conclusion

Nylon insert lock nuts are essential components in any assembly that requires reliability and resistance to loosening. Knowing what is nylon insert lock nut, how to use nylon insert lock nut, and how to remove nylon insert lock nut ensures that your projects are secure and long-lasting.

By understanding nylon insert lock nut dimensions, following size charts, and respecting torque specifications, you can achieve professional results whether in automotive, industrial, or DIY applications.

Investing in quality nylon insert lock nuts and using them correctly can save time, reduce maintenance, and prevent failures in critical assemblies. Keep this guide handy, refer to the charts when selecting sizes and torque, and your fasteners will remain secure under vibration and stress.

👉 Explore our detailed Nut Size Chart! Learn about various types of nuts, the materials they are made from, and their common applications. This guide helps you choose the right nut for any project, ensuring secure and reliable fastening. Read the full post to get all essential details!