When it comes to threading holes, whether for mechanical projects, DIY tasks, or industrial applications, selecting the correct tap drill size is crucial. The tap drill size determines how much material is removed before threading, ensuring strong, precise threads without damaging the workpiece or the tap itself. In this guide, we’ll walk you through everything you need to know about tap drill sizes, including metric and imperial standards, formulas, charts, and practical tips to make your work easier and more accurate.

What is a Tap Drill?

A tap drill is the hole drilled before threading, acting as a “starter hole” that helps the tap cut threads smoothly and accurately. Choosing the correct size is vital—too small, and the tap may bind or break; too large, and threads will be loose or weak. The right size depends on the screw’s diameter and thread spacing, measured as pitch in metric systems or threads per inch in imperial systems.

Metric Tap Drill Sizes

Metric tap drill sizes follow the ISO metric system, which uses millimeters to define screw diameters and thread spacing. Metric systems are commonly used worldwide, especially in manufacturing, engineering, and DIY projects that involve standardized fasteners.

Choosing the correct metric tap drill size ensures that your bolts and screws fit perfectly and that the threads you cut are durable and precise. This is particularly important when working with metal, hard plastics, or other materials where thread strength matters.

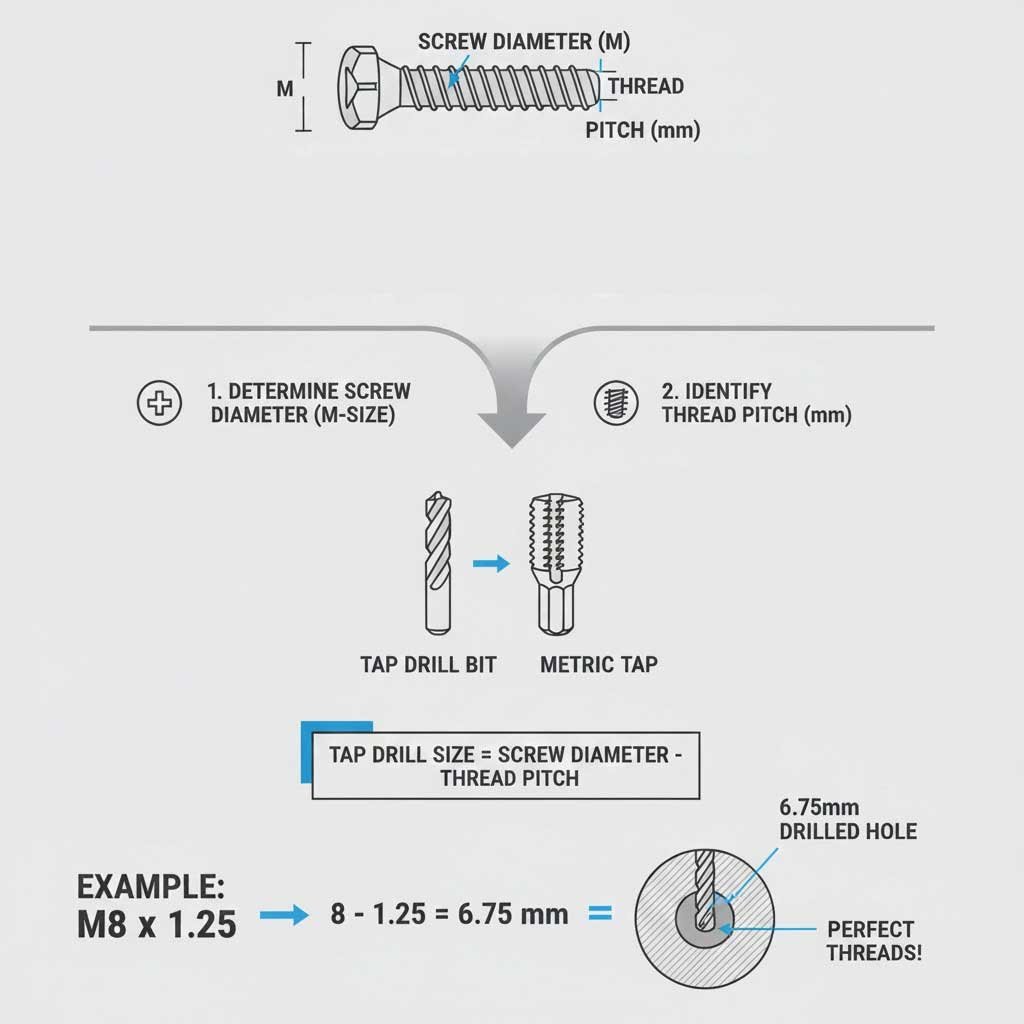

How to Choose the Right Metric Tap Drill Size

Selecting the right metric tap drill size is essential for creating strong, accurate threads. It ensures screws fit securely and prevents tap breakage. By understanding the screw’s diameter and thread pitch, you can choose a drill bit that creates the perfect hole, balancing strength and precision for every project.

1. Understanding Screw Diameter

The diameter of a screw is the distance across its widest point. Knowing this measurement is the first step in choosing a tap drill. A hole that closely matches the screw’s diameter allows the tap to form precise threads while keeping the connection strong and secure.

2. Knowing Thread Pitch

Thread pitch is the distance between each thread along the screw’s length. Metric screws use millimeters to measure this spacing. Accurate knowledge of thread pitch ensures the tap can cut properly, creating threads that grip tightly without stripping or becoming loose, which is essential for the stability and durability of the connection.

3. Choosing the Right Drill Size

The correct tap drill size is slightly smaller than the screw’s outer diameter. This allows threads to form fully and grip the material. Using the wrong drill size—either too large or too small—can weaken the threads or risk breaking the tap, so precise measurement is key for reliable results.

4. Ensuring Strong, Clean Threads

A properly sized tap drill creates threads that are strong and durable. Smaller holes help threads bite into the material, while larger holes risk loose or weak threads. By carefully considering diameter and pitch, you can achieve clean, precise threads that hold securely, making your projects safer and more professional.

Common Metric Tap Drill Sizes

When working with metric screws, having a reference for tap drill sizes makes threading much easier and more accurate. The chart below lists common screw sizes, their thread pitch, and the recommended tap drill size in millimeters. For less common bolts, it’s always best to consult a full metric tap drill chart to ensure precise and strong threads.

| Thread Size | Pitch | Tap Drill Size (mm) |

|---|---|---|

| M3 | 0.5 | 2.5 |

| M4 | 0.7 | 3.3 |

| M5 | 0.8 | 4.2 |

| M6 | 1.0 | 5.0 |

| M8 | 1.25 | 6.75 |

| M10 | 1.5 | 8.5 |

| M12 | 1.75 | 10.25 |

| M16 | 2.0 | 14.0 |

| M20 | 2.5 | 17.5 |

This chart is helpful for common bolts and screws. For less common thread sizes, always refer to a detailed metric tap drill chart.

Tips for Metric Tapping

Proper preparation makes metric tapping easier and ensures strong, clean threads. Follow these practical tips to get the best results:

Mark the spot: Use a center punch before drilling to keep the bit from wandering.

Lubricate the tap: Apply cutting oil for smoother cutting and less friction.

Work carefully with hard metals: Drill a little at a time, clearing chips often, to avoid overheating and breaking the tap.

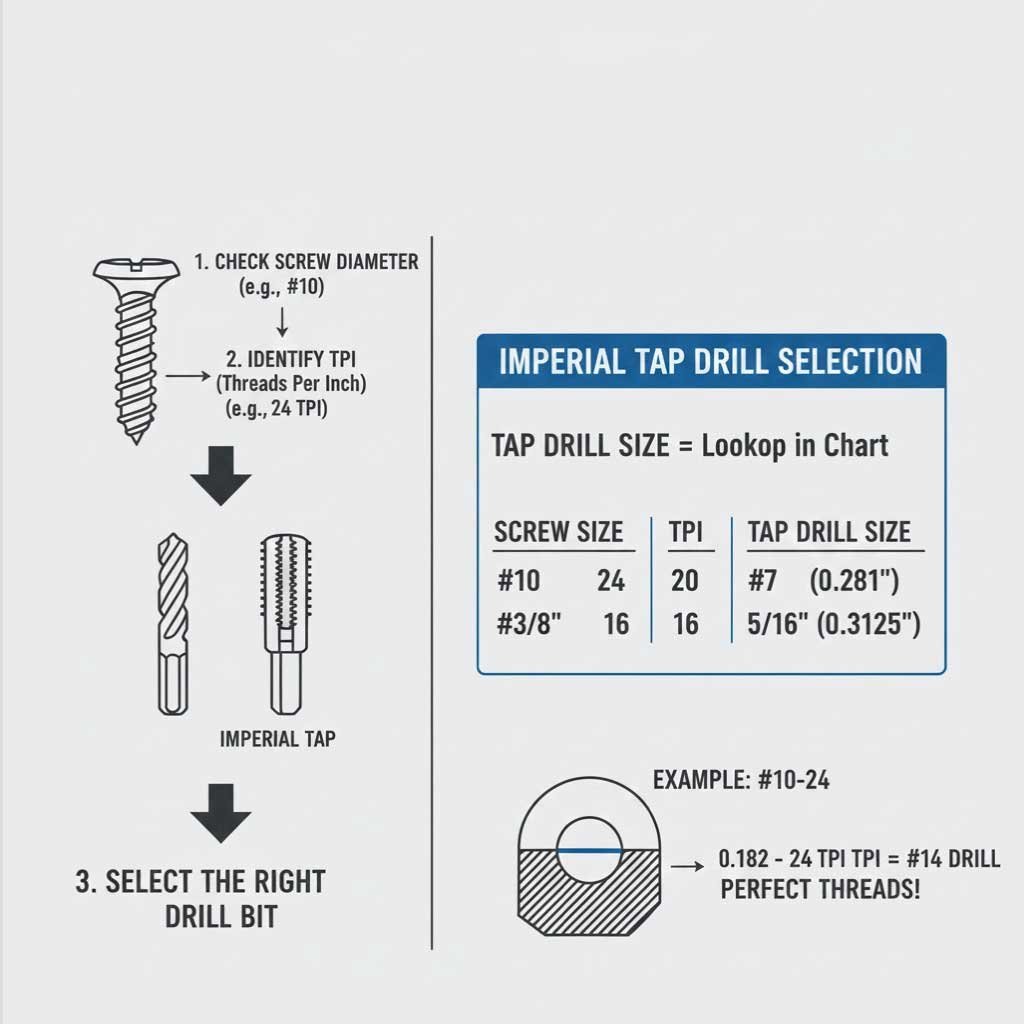

Imperial Tap Drill Sizes

Imperial taps use measurements in inches, with thread spacing defined as Threads Per Inch (TPI). Choosing the correct drill size is key for strong, accurate threads.

Check the screw diameter: Know the outer width of the screw before drilling.

Understand TPI: Threads per inch determine how close together the threads are.

Select the right drill bit: Use a slightly smaller hole than the screw diameter to allow the tap to form full, tight threads.

Common Imperial Tap Drill Sizes

Using the correct tap drill size is essential when working with imperial screws. The chart below lists common thread sizes, their threads per inch (TPI), and the recommended drill bit for tapping. For fine threads, slightly smaller holes are needed to ensure strong, precise threads and secure connections.

| Thread Size | TPI | Tap Drill Size (inches) | Drill Bit Number |

|---|---|---|---|

| #4-40 | 40 | 0.082 | #44 |

| #6-32 | 32 | 0.106 | #36 |

| #8-32 | 32 | 0.136 | #29 |

| #10-24 | 24 | 0.190 | F |

| 1/4″-20 | 20 | 0.200 | #7 |

| 5/16″-18 | 18 | 0.257 | #3 |

| 3/8″-16 | 16 | 0.312 | 5/16″ |

| 1/2″-13 | 13 | 0.375 | 3/8″ |

Imperial charts can also include UNC (coarse) and UNF (fine) threads. Fine threads need slightly smaller tap drills due to higher thread count per inch.

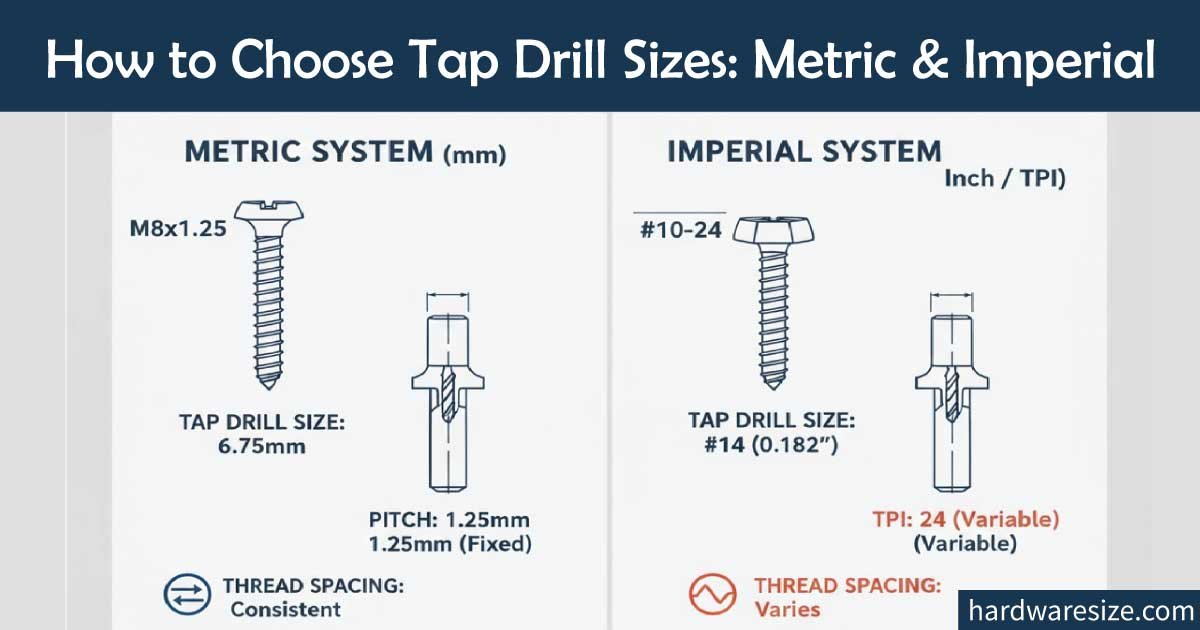

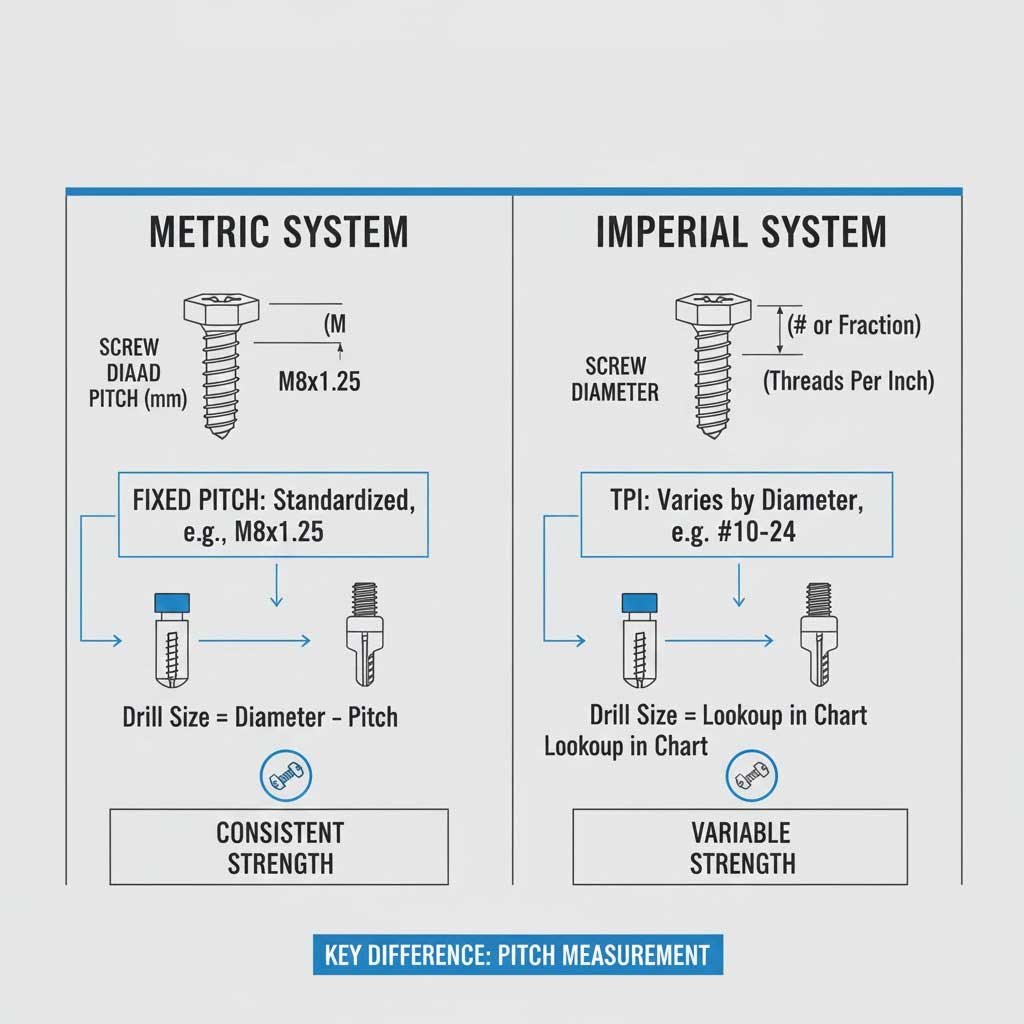

Why Tap Drill Sizes Differ Between Metric and Imperial

Metric and imperial threads differ in how they are measured and calculated. Metric threads are measured in millimeters with fixed pitches, making calculations straightforward. Imperial threads use inches and threads per inch (TPI), requiring a bit more conversion. Choosing the correct system is important to ensure strong, durable threads and that screws fit securely and safely.

-

Metric threads are measured in mm and have fixed pitches.

-

Imperial threads are measured in inches and use threads per inch (TPI).

-

Metric threads are simpler for calculations, while imperial threads require TPI conversion.

-

Using the correct system ensures thread strength, durability, and proper screw fit.

How to Read a Tap Drill Chart

Tap drill charts are essential for selecting the right drill size for threading. They provide information about screw size, thread spacing, and recommended drill bits. Some charts even show thread engagement, helping you adjust for different materials. Understanding charts ensures accurate, strong threads and reduces mistakes when tapping holes in metal, plastic, or wood.

-

Screw size (metric or imperial)

-

Thread pitch/TPI

-

Recommended hole size

-

Percentage of thread engagement (how tight the threads are)

-

Tip: For stronger threads in soft materials like aluminum, you can slightly undersize the hole for maximum thread engagement. For hard materials like steel, slightly oversize can prevent tap breakage.

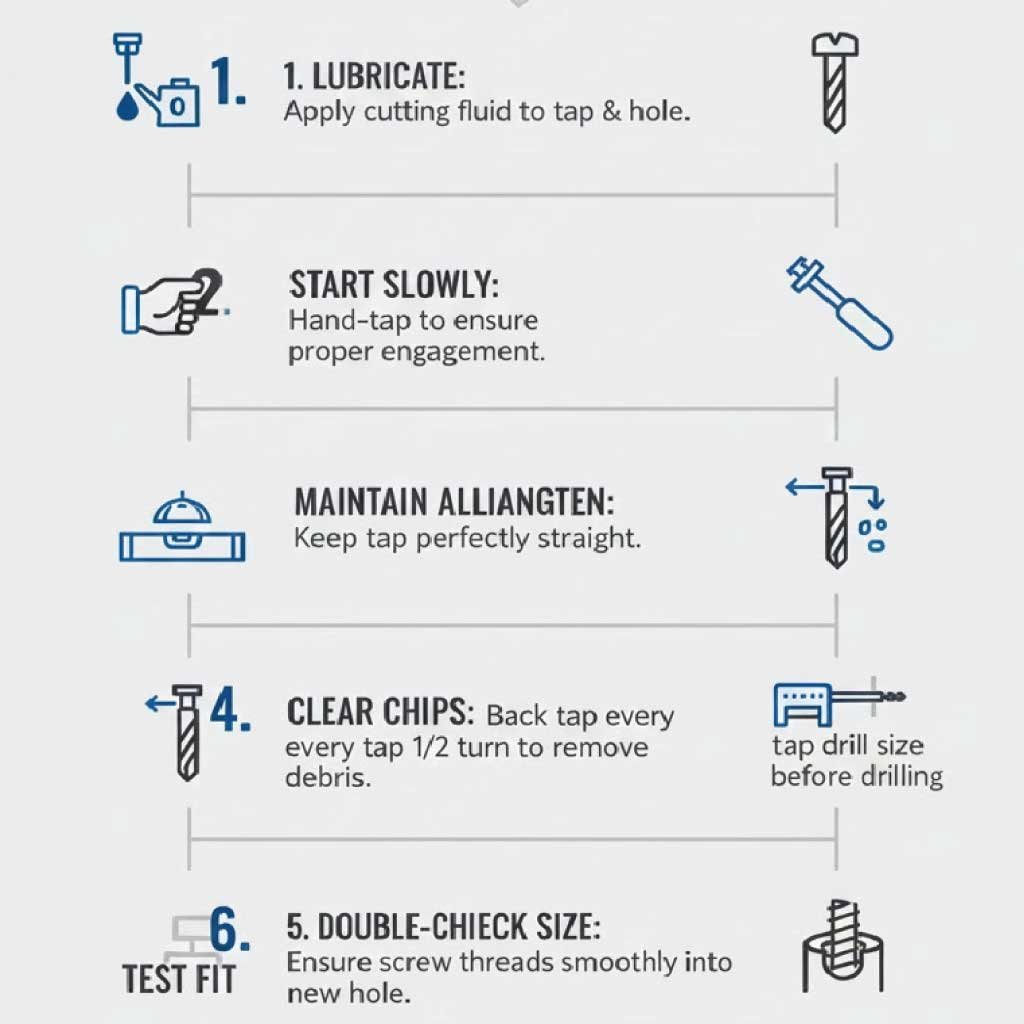

Practical Tips for Tapping Holes

Tapping holes requires care and proper technique. Lubrication, slow tapping, correct alignment, and regular chip removal are essential for clean, strong threads. Always double-check drill sizes before starting. Following these tips helps prevent tap breakage, ensures precise threads, and makes the process smoother, whether you’re working on a small DIY project or a professional mechanical task.

Lubrication is Key: Always use cutting oil on steel and harder metals. Lubrication reduces heat, friction, and wear on the tap.

Start Slowly: Begin tapping by hand before using machines. Hand tapping gives better control.

Correct Alignment: Ensure the tap is perpendicular to the surface. Even a 1–2 degree misalignment can ruin threads.

Clear Chips Frequently: Reverse the tap slightly every few turns to break chips and prevent binding.

Check Drill and Tap Sizes: Always double-check your tap drill size against a reliable chart before starting.

👉 Discover the Complete Drill & Drill Bit Guide covering all types, sizes, and uses. Learn how to choose the right drill bit, understand different drill types, and master proper drilling techniques. Read the full post to make your DIY and professional projects easier, safer, and more precise.

Tap Drill Chart Resources

Using tap drill charts saves time and prevents mistakes, especially when working with both metric and imperial threads. There are many resources available online, in print, or as digital calculators. Machinists and DIY enthusiasts use these tools to select the correct drill size, convert measurements, and ensure precise, strong threads for all kinds of projects.

-

Pocket tap drill guides

-

PDF charts for quick reference

-

Online calculators that automatically convert metric to imperial and vice versa

Using charts prevents mistakes and saves time when working on mechanical or DIY projects.

When to Use a Pilot Hole

A pilot hole is a smaller, preliminary hole drilled before the final tap drill size. It is especially useful when working with large screws or bolts, hard metals like stainless steel or cast iron, and long taps where chip buildup could be a problem. Creating a pilot hole helps guide the tap accurately, keeps it aligned, and reduces the stress on both the tap and the material, making threading smoother, safer, and more precise.

Thread Engagement and Hole Strength

Thread engagement refers to how much of the screw’s threads actually make contact with the material. Choosing the correct tap drill size ensures strong threads and secure connections. For most metals, 75–80% engagement provides optimal strength. Softer metals, like aluminum or brass, benefit from slightly higher engagement, while harder metals, such as steel, may require slightly less. Threads that are too tight can strip easily, whereas loose threads weaken the hold and reduce overall connection strength.

Quick Conversion Between Metric and Imperial

In many projects, you may encounter both metric and imperial fasteners. Knowing quick equivalents between the two systems helps save time, ensures proper fit, and allows you to select the right drill and tap sizes without confusion or mistakes.

| Metric | Imperial |

|---|---|

| M6 | 1/4″ |

| M8 | 5/16″ |

| M10 | 3/8″ |

| M12 | 1/2″ |

| M16 | 5/8″ |

These conversions help when working with mixed toolkits or imported materials.

Conclusion

A tap drill size chart is an essential tool for anyone working with threaded fasteners, from woodworking and metalworking to DIY projects. Understanding the differences between metric and imperial sizes, selecting the correct hole diameter, and using charts properly helps reduce tap breakage, ensure strong threads, save time and material, and improve overall project quality. With proper preparation, tapping holes becomes accurate, efficient, and stress-free, producing threads that hold securely and last.