Washers may look like small, simple hardware components, but choosing the correct washer size and type plays a critical role in the strength, safety, and durability of any mechanical or construction project. Whether you’re working on home repairs, automotive assemblies, industrial machinery, or DIY projects, understanding washer size charts can save time, prevent damage, and improve load distribution.

This complete guide covers flat washers, spring washers, and lock washers, along with easy-to-read size charts, practical tips, and common mistakes to avoid.

What Is a Washer and Why Size Matters

A washer is a thin, flat, or specially shaped disk with a center hole, placed between a bolt or nut and the surface being fastened. Its main purposes include distributing load evenly, protecting surfaces from damage, reducing friction, improving joint stability, and helping prevent fasteners from loosening due to vibration or repeated use over time.

- Distributing load evenly

- Preventing surface damage

- Reducing vibration

- Improving joint stability

- Preventing loosening over time

Choosing the wrong washer size can lead to uneven pressure, loose joints, stripped threads, or material damage. That’s why washer size charts are essential.

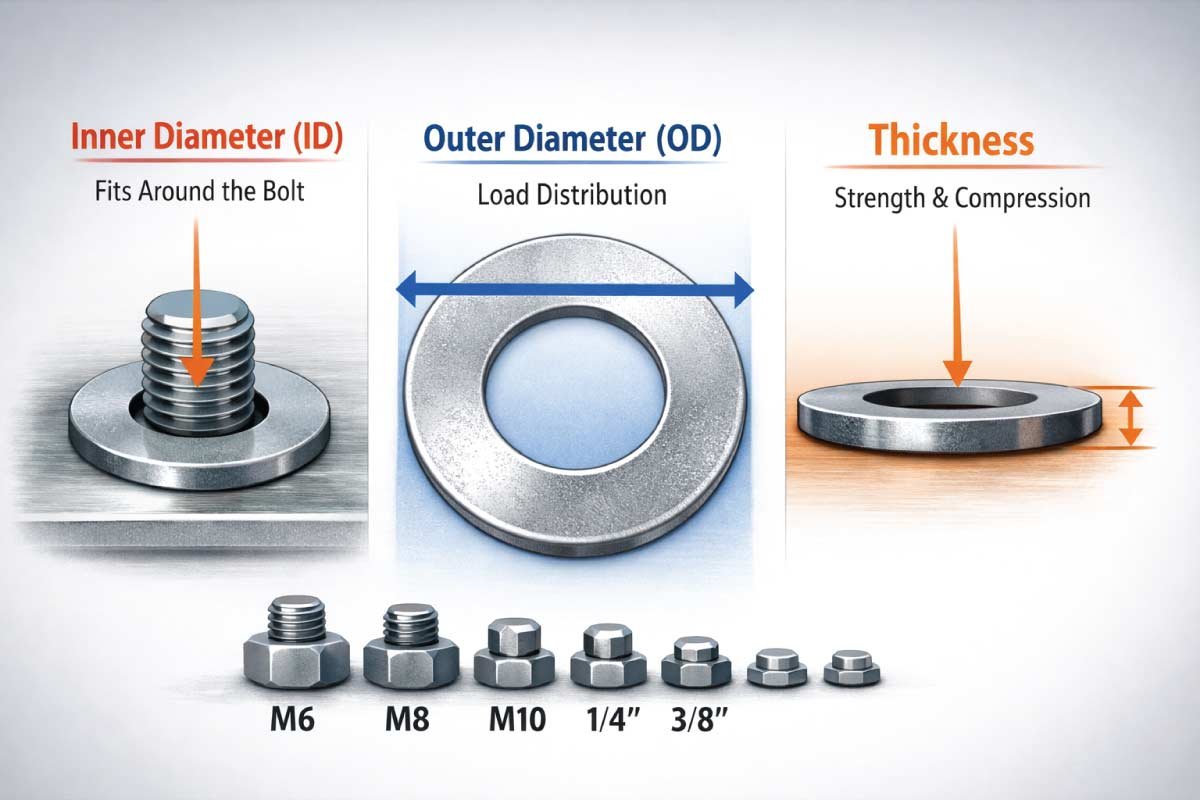

Understand Washer Measurements

Before using any washer size chart, it’s important to understand the three basic measurements that define how a washer fits and performs. These dimensions ensure proper alignment with the fastener, balanced load distribution, and reliable joint strength. Selecting the correct measurements helps prevent loosening, surface damage, and uneven pressure during installation and long-term use.

Inner Diameter (ID) – Fits around the bolt or screw

Outer Diameter (OD) – Determines load distribution

Thickness – Affects strength and compression

Washers are usually sized to match standard bolt sizes such as M6, M8, M10, 1/4″, 3/8″, and so on.

Flat Washer Size Chart (Metric & Imperial)

| Bolt Size | Inner Diameter (mm/in) | Outer Diameter (mm/in) | Thickness (mm/in) |

|---|---|---|---|

| M4 | 4.3 mm | 9 mm | 0.8 mm |

| M6 | 6.4 mm | 12 mm | 1.6 mm |

| M8 | 8.4 mm | 16 mm | 1.6 mm |

| M10 | 10.5 mm | 20 mm | 2.0 mm |

| 1/4″ | 0.281″ | 0.734″ | 0.065″ |

| 3/8″ | 0.406″ | 1.000″ | 0.065″ |

Best uses for flat washers:

- Wood and metal surfaces

- Structural assemblies

- Automotive and machinery applications

- General fastening

Spring Washer Size Chart

Spring washers, also known as split washers, are specifically designed to prevent fasteners from loosening due to vibration or thermal expansion. Their split, coiled shape creates constant tension when compressed, helping maintain pressure on the bolt or nut and improving joint stability in moving or high-stress applications.

| Bolt Size | Inner Diameter | Outer Diameter | Thickness |

|---|---|---|---|

| M5 | 5.1 mm | 9.2 mm | 1.3 mm |

| M6 | 6.1 mm | 11.8 mm | 1.6 mm |

| M8 | 8.1 mm | 14.8 mm | 2.0 mm |

| M10 | 10.2 mm | 18.1 mm | 2.5 mm |

| 1/4″ | 0.260″ | 0.500″ | 0.070″ |

| 3/8″ | 0.385″ | 0.688″ | 0.098″ |

Best uses for spring washers:

- Vibrating machinery

- Motors and engines

- Electrical panels

- Automotive components

Lock Washer Size Chart

Lock washers are specifically designed to prevent fasteners from loosening under vibration or movement. They achieve this by creating resistance between the nut or bolt and the surface. Lock washers come in several designs, including toothed, internal tooth, external tooth, and split lock washers, each suited for different applications.

| Bolt Size | Inner Diameter | Outer Diameter | Type |

|---|---|---|---|

| M6 | 6.4 mm | 11 mm | External Tooth |

| M8 | 8.4 mm | 15 mm | Internal Tooth |

| M10 | 10.5 mm | 18 mm | Split Lock |

| 1/4″ | 0.281″ | 0.500″ | Internal Tooth |

| 3/8″ | 0.406″ | 0.750″ | External Tooth |

Best uses for lock washers:

- High-vibration environments

- Electrical grounding

- Automotive and industrial assemblies

- Safety-critical joints

Flat vs Spring vs Lock Washers (Quick Comparison)

Choosing the right washer type depends on how much load support, vibration resistance, and fastening security your project requires. Flat, spring, and lock washers each serve a different purpose, and understanding their key differences helps ensure stronger joints, better surface protection, and long-term reliability in both simple and demanding applications.

| Feature | Flat Washer | Spring Washer | Lock Washer |

|---|---|---|---|

| Load distribution | Excellent | Limited | Moderate |

| Vibration resistance | Low | Medium | High |

| Surface protection | High | Low | Medium |

| Prevents loosening | No | Yes | Yes |

| Common applications | General use | Machinery | Safety joints |

🛠️ Looking for the perfect nut for your project? Our Nut Size Chart: Types, Materials and Applications guide makes it easy to choose the right nut for any fastener, material, or load. Discover detailed charts, material tips, and practical advice to ensure strong, reliable assemblies. Read the full post to master nut selection and avoid costly mistakes.

How to Choose the Right Washer Size

Choosing the correct washer is not just about size, it’s also about application, load conditions, and the environment in which the fastener will be used. The right washer improves joint strength, prevents damage, and reduces the risk of loosening over time, especially in demanding or high-stress situations.

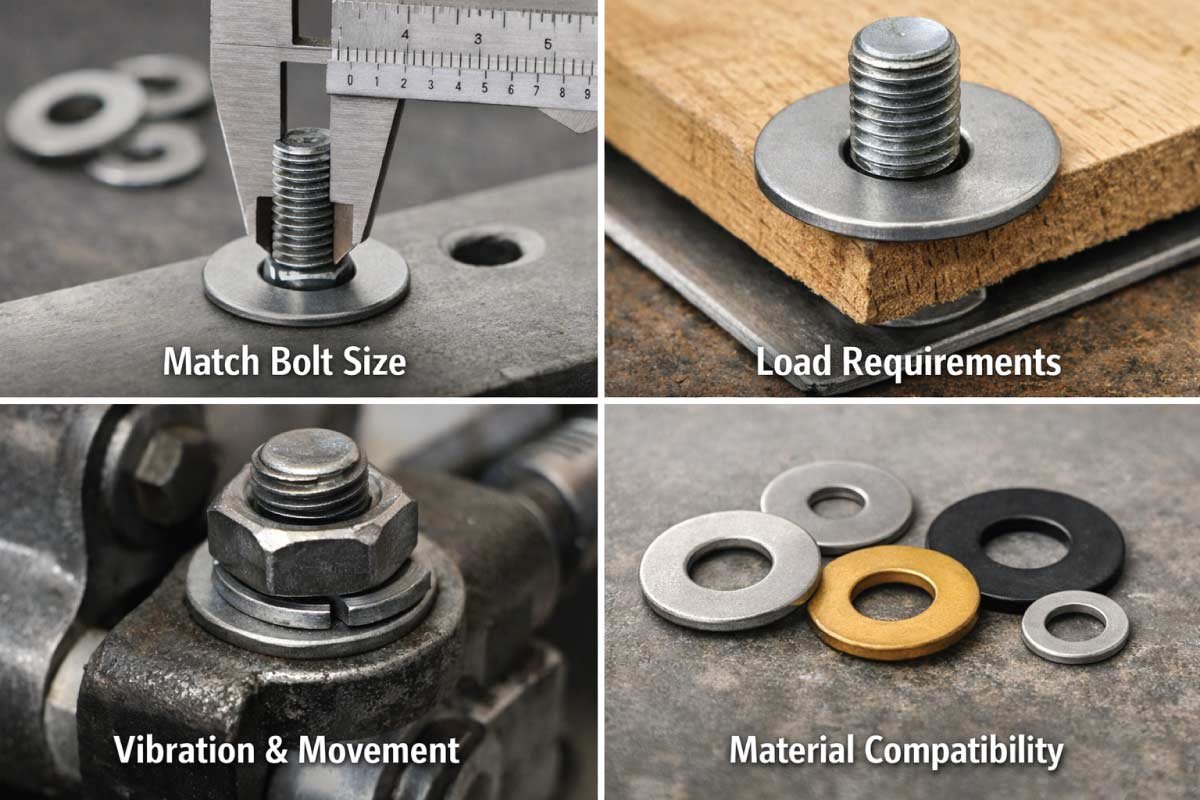

1. Match Washer to Bolt Size

Always choose a washer with an inner diameter slightly larger than the bolt diameter. This allows the washer to sit properly without binding, ensures even pressure distribution, and makes installation easier while maintaining a secure and stable connection.

2. Consider Load Requirements

Load requirements play a major role in washer selection. For soft materials like wood, plastic, or thin metal sheets, large-OD flat washers help spread the load over a wider area, reducing surface damage and preventing the fastener from pulling through.

3. Check Vibration Levels

In applications exposed to constant movement or vibration, washer choice becomes critical. Spring washers or lock washers help maintain tension on the fastener, reducing the chances of loosening and improving long-term joint reliability in machinery or mechanical assemblies.

4. Material Compatibility

Washer material should match the application environment and fastener type. The right material improves durability, corrosion resistance, and overall performance, especially in electrical, outdoor, or lightweight applications.

Common washer materials include:

- Stainless steel (corrosion resistance)

- Carbon steel (high strength)

- Brass (electrical applications)

- Nylon (insulation and lightweight needs)

Common Washer Size Mistakes to Avoid

Selecting the wrong washer size or type is a common mistake that can compromise the strength and safety of your assembly. Even small errors can lead to loosening, uneven load distribution, or surface damage. Understanding these pitfalls helps ensure a secure, long-lasting, and reliable fastening solution.

- Using oversized washers that reduce grip

- Using undersized washers that don’t fit the bolt properly

- Mixing metric and imperial sizes

- Using flat washers where lock washers are required

- Ignoring washer thickness in high-load applications

Avoiding these mistakes improves safety and extends the life of your assembly.

Washer Standards You Should Know

Washers are manufactured according to recognized international standards to ensure consistency, reliability, and proper fit across different applications. Following these standards helps prevent mismatched parts, improves assembly safety, and guarantees performance under load. Familiarity with these specifications is essential for both professional and DIY projects.

- ISO 7089 / ISO 7090 – Metric flat washers

- DIN 125 / DIN 127 – Flat and spring washers

- ANSI B18.22.1 – Inch washer standards

Knowing these standards ensures compatibility and quality.

When to Use Large OD or Fender Washers

Large outer diameter (OD) or fender washers are used when extra load distribution is needed, especially on soft or thin materials like wood, plastic, or sheet metal. They prevent fasteners from pulling through or damaging the surface, provide greater stability, and improve joint strength. These washers are also useful for oversized holes, reducing stress concentration and ensuring a secure, long-lasting connection in critical applications.

Final Thoughts

Understanding and using a washer size chart for flat, spring, and lock washers is essential for safe, professional, and long-lasting fastening. The right washer protects surfaces, improves load distribution, and prevents costly failures caused by vibration or loosening.

Whether you’re a DIY enthusiast, mechanic, engineer, or contractor, keeping these washer charts handy will help you make better decisions on every project.

🛠️ Need the right drill for your screws? Our Tap Drill Size Chart for Metric and Imperial Screws helps you select the perfect drill bit every time. Learn accurate sizes, avoid thread damage, and ensure strong, precise assemblies. Check out the full post for detailed charts and practical tips to make your projects fail-proof.